As a material interwoven with high-strength glass fiber yarns, fiberglass cloth plays an important role in modern construction and industrial fields. It is often used for a variety of purposes such as wall reinforcement, waterproof layer reinforcement, and reinforcement layer of composite materials. Due to its excellent physical and chemical properties, such as high temperature resistance, high tensile strength, and strong corrosion resistance, fiberglass cloth has become one of the indispensable materials in many engineering projects.

With the continuous development of building materials technology, the application scope of fiberglass cloth is also expanding. In addition to the traditional construction field, it is also widely used in aerospace, automobile manufacturing, sporting goods and other industries. For example, in the construction field, fiberglass mesh can effectively improve the structural stability and durability of the wall; in industrial manufacturing, it can be used as part of the composite material to increase the strength and durability of the product.

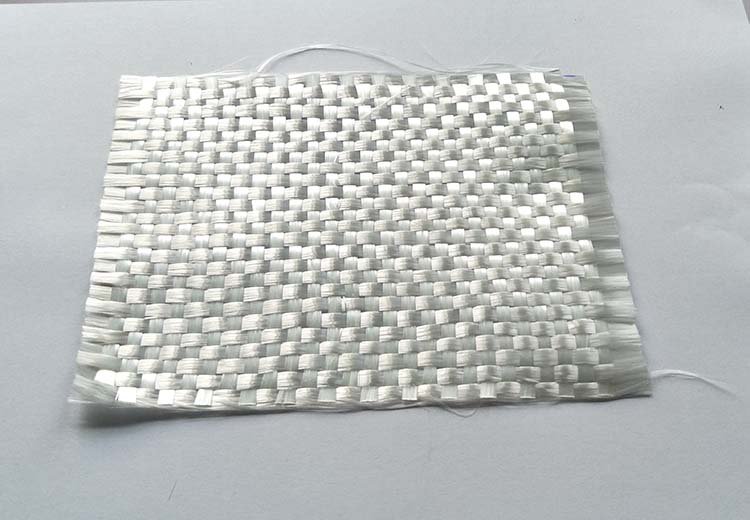

Fiberglass fabric is a mesh material woven from high-strength fiberglass yarns, which is widely used in many fields such as construction and industrial manufacturing due to its excellent physical and chemical properties. This material not only has good heat resistance, corrosion resistance and tensile strength, but also has light weight and relatively low cost, making it an ideal choice for a variety of engineering projects.

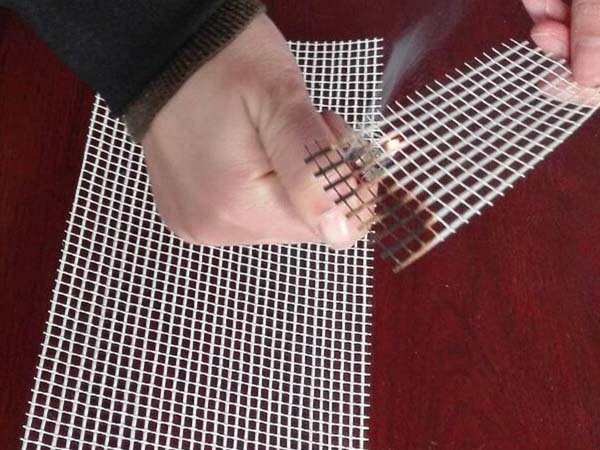

Fiberglass cloth is mainly made of glass fiber yarns composed of silicon dioxide (SiO2) and other minerals such as calcium, magnesium, aluminum, etc. through a specific weaving or knitting process. These fibers are melted at high temperature and drawn into thin fibrous materials, and then cooled and solidified to form fiberglass yarns with certain specifications and strength. These yarns are then woven into a grid-like structure to form the final product – fiberglass mesh.

The process of producing fiberglass cloth mainly includes two steps: fiber preparation and weaving. First, the raw materials are melted at high temperature and pulled into extremely fine fibers. Some special additives may be added during this process to improve the properties of the fibers. Then, these fibers are woven or knitted into a mesh structure. This process can be done manually or with automated equipment. Finally, depending on different application requirements, the finished product may undergo subsequent processing such as coating and cutting.

The history of fiberglass mesh can be traced back to the 1930s, when people began to explore the possibilities of fiberglass as a reinforcing material. In the 1950s, with the advancement of technology, glass fiber began to be produced commercially on a large scale and was gradually used in construction and industrial manufacturing. Since then, fiberglass mesh has received widespread attention due to its unique properties.

In recent years, with the continuous advancement of material science and technology, the production process of glass fiber mesh has also been significantly improved. New fiber drawing technology and weaving methods further optimize the performance of glass fiber mesh. For example, by using more advanced wire drawing technology, glass fibers with thinner diameter and higher strength can be produced; while new weaving technology can make fiberglass mesh more flexible and durable.

The reason why fiberglass cloth can stand out in many application fields is largely due to its unique physical properties, chemical stability and excellent mechanical properties. These characteristics not only ensure the reliability of fiberglass mesh under various complex conditions, but also provide users with a variety of options.

Fiberglass mesh is widely used in many fields due to its excellent performance, especially in construction, industrial manufacturing and some other special industries.

Fiberglass cloth have demonstrated strong applicability and superiority in many fields such as construction and industrial manufacturing due to their high temperature resistance, tensile strength, corrosion resistance, chemical stability and excellent mechanical properties. They have played an indispensable role in meeting the needs of different industries for high-performance materials.

As a fiberglass manufacture, Niumaterial is committed to providing high-quality and high-performance glass fiber products. We continue to explore the application of new technologies and new materials, striving to maintain a leading position in the fierce market competition and meet the needs of customers.

If you have any questions

Please contact us for free consultation and product quotation

Table of Contents Add a h

Table of Contents Add a h