Precision Sanding, Ship-Class Excellence

Dry, Wet & Curved Surfaces – Sandpaper Engineered for Marine Mastery

Choosing The Right Sandpaper For Your Project

Three Sandpaper Systems, 360° Marine Surface Solutions

Dry Sandapper

Description: Rigid aluminum oxide abrasives on tear-resistant cloth backing, optimized for rapid dry grinding to remove rust and wood splinters.

Application: Critical for grinding steel hull welds, pre-leveling deck wood, and dock-side metal surface preparation in marine construction.

Water Sandpaper

Description: Silicon carbide grit on waterproof backing enables cool wet sanding (P800-P2000) for heat-sensitive surfaces.

Application: Ensures blister-free polishing of marine epoxy coatings and ultra-smooth finishes on yacht decks.

Membrane Sandpaper

Description: 0.25mm polyester film with flexible abrasive coating for contour-hugging precision on complex shapes.

Application: Perfect for propeller curves, carbon fiber hulls, and FRP laminate finishing in high-speed crafts.

Find The Best Specification For Your Project

Niumaterial Sandpaper for fiberglass shipbuilding materials are available in a variety of gauges, enabling you to precisely match your project

ensuring optimum performance and meeting your specific needs.

Unique Features Of Sandpaper For Shipbuilding Materials

Niumaterial versatile Sandpaper can meet the needs of your diverse projects, guaranteeing superior performance and cost-effectiveness.

Niumateria’s Dry Sandpaper uses high-quality abrasives with a unique formula and particle distribution design, offering high grinding efficiency to quickly remove old paint and rust from the ship’s surface, significantly improving work efficiency and ensuring consistent grinding performance.

Dry Sandpaper is coated with an anti-static layer, which effectively prevents the adhesion of dust caused by static electricity, keeping the sandpaper clean and extending its service life. This feature is particularly useful in shipbuilding processes where high cleanliness is required, reducing the decline in grinding performance due to dust adhesion caused by static electricity.

The paper base of Dry Sandpaper is made of latex paper, which is more flexible and can adapt to grinding different shapes of the ship’s surface. This flexibility allows it to better fit complex ship structures, ensuring even grinding results and making it suitable for various complex grinding tasks.

The abrasives of Water Sandpaper are fine in texture, suitable for fine grinding of the ship’s surface, making it smoother and providing a good base for subsequent painting. The fine abrasive particles effectively reduce grinding marks, improving the smoothness and gloss of the ship’s surface.

Membrane Sandpaper has good flexibility and durability, maintaining good performance after multiple grinding operations. Its durability not only reduces the cost of sandpaper replacement but also ensures stability and reliability in complex shape grinding tasks.

Customized To Your

Unique Needs

Niumaterial understands that every project and application is unique, turning your vision into reality with tailor-made fiberglass shipbuilding materials Sandpaper solutions.

Product Solutions

For traders, Niumaterial will provide you with complete product solutions.

For manufacturers, we will recommend specifications suitable for your project, Provide technical parameters, etc.

Product Customization

Niumaterial offer a range of product customization options to ensure our products meet your specific needs.

Including fiber length, sizing compatibility,special specification customization, etc.

Packaging Customization

Whether you need carton packaging, woven packaging, tube packaging, tray packaging.

Or other additional custom packaging (special labels, branding, etc.)

Free Sample Test

Niumaterial can provide you with free samples for testing, and you can accurately detect in your own environment whether our products are suitable for your project needs.

Join Niumaterial Customer Group

From North America to Europe, from Asia to Africa, and even further afield, Niumaterial shipbuilding materials has entered diversified markets.

Niumaterial Fiberglass

shipbuilding materials

Niumaterial is a professional Shipbuilding Material enterprise with more than 20 years of experience. It has efficient production equipment, high processing precision and assembly technology. It mainly produces and sells Vacuum infuion products tools,fiberglass woven roving, fiberglass chopped strand mat etc.

The Impact Of Trust: Niumaterial Customer Visit

Experience Niumaterial modern factories, professional services and genuine hospitality.

Australia Hull Materials Company

Afghanistan Marine Coatings Supplier

Middle East Marine Composites Manufacturer

United States Marine Fireproofing Contractor

United States Marine Fireproofing Contractor

Marine Repair Materials Supplier in India

Polish Marine Lightweight Materials Trader

Russia Marine Lightweight Materials

Niumaterial Extraordinary Performance At The Exhibition

Build global connections: explore collaborations and tailor solutions for a diverse customer base.

JEC Composites Exhibition

BIG5 Dubai

Canton Fair

Canton Fair

JEC Composites Exhibition

BAU Exhibition

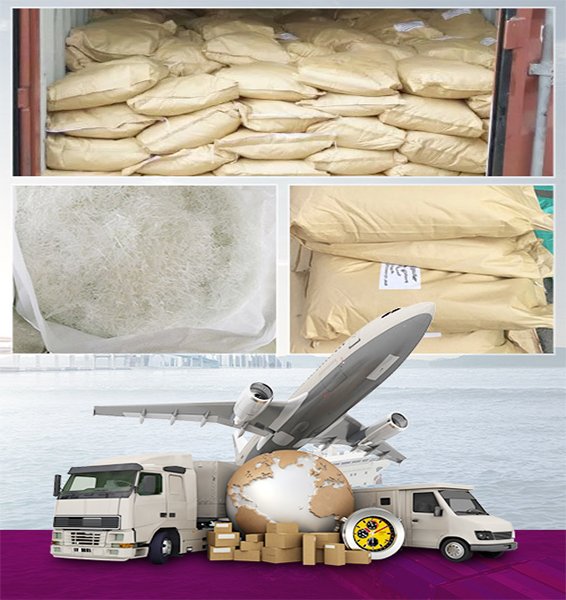

Efficient packaging and shipping solutions

From strict production to safe transportation, Niumaterial guarantees product integrity and timely delivery.

Package

1. Niumaterial fiberglass chopped strands are packed in kraft bags or woven bags, with good moisture resistance, about 25 kg per bag, 4 bags per layer, 8 layers per pallet, 32 bags, and packed with multi-layer shrink film and packing tape. 2. One ton and one bag. 3. 1kg small bag or Naturally soluble packaging Can be customized according to your requirements

Transportation

Niumaterial fiberglass supports multiple shipping methods (sea shipping, air shipping, rail shipping), we can recommend the best shipping method for you.

Delivery Detail

15 days after receiving the deposit.

Listen To Real Customer Feedback

Learn how some of Niumaterial customers have found success with Niumaterial Fiberglass Shipbuilding Material Sandpaper

Listen To Real Customer Feedback

Learn how some of Niumaterial customers have found success with Niumaterial Fiberglass Shipbuilding Material Sandpaper

Frequently Asked Questions About Sandpaper

These Q&A are designed to address the doubts and concerns customers may have when considering doing business with Niumaterial by providing transparent information and timely support.

Dry Sandpaper is mainly used for removing old paint layers, rust, and performing coarse grinding on the ship's surface. Water Sandpaper is suitable for wet grinding processes, such as fine grinding before painting on the ship's surface. It can effectively prevent clogging and provides a smoother surface after grinding. Membrane Sandpaper is ideal for grinding complex shapes on the ship's surface, like curves and corners. Its flexibility allows it to fit these areas well for fine grinding.

The choice of grit size depends on the specific grinding task. Generally, for removing thick old paint layers or rust, you should choose coarse Dry Sandpaper, such as 60 or 80 grit. For wet grinding processes, like fine grinding the ship's surface before painting, you can select medium-grit Water Sandpaper, such as 180 or 240 grit. When using Membrane Sandpaper for fine grinding on complex shapes, it's common to choose finer grits, like 320 or 400 grit, to achieve a smoother surface.

Use coarse grit (e.g., 60) for coarse grinding, medium grit (e.g., 180) for wet grinding, and fine grit (e.g., 320) for fine grinding.

Dry Sandpaper can be used several times, while Water Sandpaper and Membrane Sandpaper, being more durable, can be used multiple times.

Niumaterial recommend opting for Western Union, as it offers a more favorable handling fee. However, for new clients, we currently only accept payments through 50% T/T. On the other hand, if you have been a long-standing customer and are experiencing financial constraints, Niumaterial offer the option of OA credit.

It depends on whether you need to customize, if you don't need to customize, Niumaterial can ship within 7 days if we have stock, if you don't have stock and need to customize, it will take 7~15 days!

After delivery, you will generally receive the goods in about 45 days, but the specific time you receive the goods depends on your port, shipping date, customs clearance time and other factors.

Technical Support: Niumaterial team of experts is ready to help you diagnose and resolve any technical issues or challenges you may encounter;

Customer Support: Niumaterial can provide product guidance and advice as well as order tracking and delivery updates according to your specific requirements, ensuring a smooth and hassle-free process from purchase to receipt.

PLACE YOUR ORDER TODAY TO AVAIL ALL THESS BENEFITS!

Free Samples For Testing Your Project!

50+ Fiberglass Product Catalogue!

Product Customization Plan!

Problem Solved Solution!

86-13933702587

infor1@fiberglassyn.com