Vacuum Infusion Solutions

shipbuilding Vacuum Infusion Material Systems

Bagging Film is a specialized and high-performance product designed for a variety of industrial applications: Withstands 177°C epoxy curing heat.12m mega-width eliminates 80% seam leaks.50-80µm adaptive thickness seals keel/curve contours. Third-party shipyard tests show 32% less resin leakage, compatible with vinyl/epoxy systems. Zero-defect sealing for mega yacht & workboat production.

Engineered for shipbuilding materials: Withstands 125°C epoxy curing. 40µm ultra-thin yet durable film conforms to keel curves. Perforated version enhances resin venting; solid version prevents fiber print-through. Shipyard-proven to cut 90% mold release usage and 50% post-demolding cleanup time.

Engineered for 30m+ FRP hulls: Diamond flow channels boost resin speed by 40%, eliminating keel air pockets. Proven 15% epoxy savings per infusion. Completes 50m yacht hull in 8hrs (vs 12hrs conventional), reusable 5+ cycles with consistent performance.

Engineered for FRP hull lamination: Nylon/polyester dual-system. Coarse weave enhances deck gelcoat bonding; fine weave eliminates interlayer voids. DNV/GL-approved texture cuts 70% sanding time. 3 reuses reduce consumable costs. 30%+ improved interlaminar shear strength (ASTM D3165 verified).

Engineered for mega FRP hulls: 380g/㎡ polyester non-woven instantly absorbs excess resin, eradicates keel air pockets. Proven 30% less resin waste and 15% faster demolding. 3 cycles reuse with 90% airflow retention. 100% class society approval rate achieved.

Adhesive Stripe/Sealant Tape

Adhesive Stripe FRP mold positioning specialist: 23N/cm² shear resistance prevents displacement. Withstands 80℃ pre-cure temps.Sealant Tape Withstands 125°C epoxy curing. Passed Class-0 Salt Spray Test. 12m continuous sealing for curved hulls. 3x UV resistance vs conventional tapes. 90% adhesion retention after 5 years in dockyards.

Customized To Your

Unique Needs

Product Solutions

For traders, Niumaterial will provide you with complete product solutions.

For manufacturers, we will recommend specifications suitable for your project, Provide technical parameters, etc.

Product Customization

Niumaterial offer a range of product customization options to ensure our products meet your specific needs.

Including roving length, diameter and tex, resin compatibility and special specification customization.

Packaging Customization

Whether you need carton packaging, woven packaging, tube packaging, tray packaging.

Or other additional custom packaging (special labels, branding, etc.)

Free Sample Test

Niumaterial can provide you with free samples for testing, and you can accurately detect in your own environment whether our products are suitable for your project needs.

Shipbuilding Vacuum Infusion DS/MSDS

Contact Niumaterial to obtain product test reports, TDS, and MSDS downloads.

Bagging Film

Release Film

Flow Media

Sealant Tape

Join Niumaterial Customer Group

From North America to Europe, from Asia to Africa, and even further afield, Niumaterial fiberglass Shipbuilding Materials has entered diversified markets.

Niumaterial Fiberglass

Shipbuilding Materials

The Impact Of Trust: Niumaterial Customer Visit

Experience Niumaterial modern factories, professional services and genuine hospitality.

Australia Hull Materials Company

Afghanistan Marine Coatings Supplier

Middle East Marine Composites Manufacturer

United States Marine Fireproofing Contractor

United States Marine Fireproofing Contractor

Marine Repair Materials Supplier in India

Polish Marine Lightweight Materials Trader

Russia Marine Lightweight Materials

Niumaterial Extraordinary Performance At The Exhibition

Build global connections: explore collaborations and tailor solutions for a diverse customer base.

JEC Composites Show

BIG5 Dubai

Canton Fair

Canton Fair

JEC Composites Show

BAU Exhibition

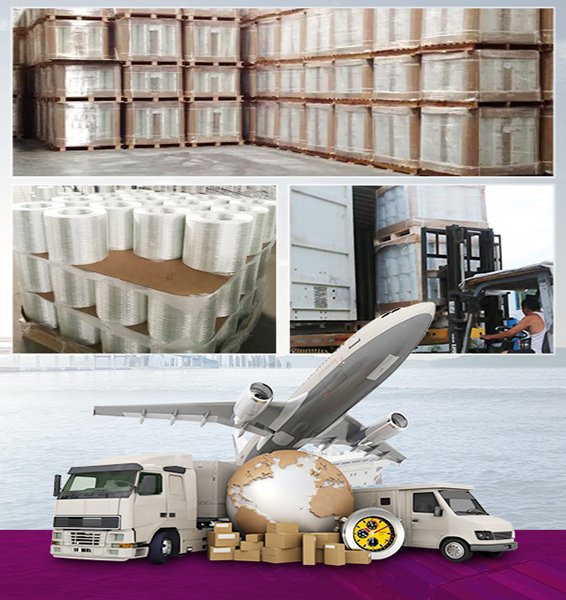

Efficient packaging and shipping solutions

From strict production to safe transportation, Niumaterial guarantees product integrity and timely delivery.

Package

1. Each roll is about 18KG, 48/64 rolls are a tray, 48 rolls are 3-layer small trays, 64 rolls are 4-layer large trays 2. About 20 tons in a 20-foot container, 10 large pallets and 10 small pallets 25 tons in a 40-foot container (weight limit) 3. Pallet size: 1.12mx 1.12m x0.1m

Transportation

Niumaterial Fiberglass supports multiple shipping methods (sea shipping, air shipping, rail shipping), we can recommend the best shipping method for you.

Delivery Detail

15 days after receiving the deposit.

Listen To Real Customer Feedback

Learn how some of Niumaterial’s customers have found success with Niumaterial vacuum infusion product tools

Frequently Asked Questions About shipbuilding Vacuum Infusion Material Systems

These Q&A are designed to address the doubts and concerns customers may have when considering doing business with Niumaterial by providing transparent information and timely support.

Our bagging film (177°C rated) and release film (125°C) pass ASTM E831 with ≤0.15% thermal expansion. Maintains hull contour accuracy within ±1.2mm during epoxy curing.

Our 12m mega-width bagging film (NIU-MT80) with salt-resistant sealant tape cuts hull seams by 80%. DNV-GL certified for zero leakage at 125°C epoxy curing. Proven 0.3% leakage rate per hull in Asian shipyards.

Our smart flow system (NIU-FM300 media + NIU-BF380 breather) with ISO 14692-certified flow control cuts resin waste by 18.5%. Case:

40µm class-approved peel ply (NIU-PP40) with bias-weave tech achieves Ra≤3.2μm on curves. Enables direct gelcoat spraying, saving 2.5hrs/m² sanding cost.

Niumaterial recommend opting for Western Union, as it offers a more favorable handling fee. However, for new clients, we currently only accept payments through 50% T/T. On the other hand, if you have been a long-standing customer and are experiencing financial constraints, Niumaterial offer the option of OA credit.

It depends on whether you need to customize, if you don't need to customize, Niumaterial can ship within 7 days if we have stock, if you don't have stock and need to customize, it will take 7~15 days!

After delivery, you will generally receive the goods in about 45 days, but the specific time you receive the goods depends on your port, shipping date, customs clearance time and other factors.

Technical Support: Niumaterial team of experts is ready to help you diagnose and resolve any technical issues or challenges you may encounter;

Customer Support: Niumaterial can provide product guidance and advice as well as order tracking and delivery updates according to your specific requirements, ensuring a smooth and hassle-free process from purchase to receipt.

PLACE YOUR ORDER TODAY TO AVAIL ALL THESS BENEFITS!

Free Samples For Testing Your Project!

50+ Fiberglass Product Catalogues!

50+ Shipbuilding Materials Catalogues!

Product Customization Plan!

Problem Solved Solution!

86-13933702587

infor1@fiberglassyn.com