Flawless Surface Quality

Faster Demolding

High-Performance Peel Ply for Superior Fiberglass Surface Finish

Fiberglass shipbuilding materials Peel Ply

Niumaterial Top-Quality Peel Ply Fiberglass for Precision Composite Manufacturing

Peel Ply is predominantly composed of either nylon or polyester, both of which are high-performance synthetic polymers known for their strength and durability.The primary purpose is to create a textured surface on composite laminates, ensuring optimal adhesion and bonding between layers.

The fabric is characterized by its weave pattern, which imparts a distinctive texture to the finished composite surface. This texture enhances the mechanical bond between the composite layers and subsequently improves the overall strength and performance of the composite structure.

Peel Ply is used in shipbuilding for post-molding surface treatment of composite parts (e.g., hulls, decks, bulkheads, rudders/fairings). When removed, it leaves a uniform texture for bonding or painting, eliminating voids, reducing finishing labor, and enhancing adhesion strength and production efficiency.

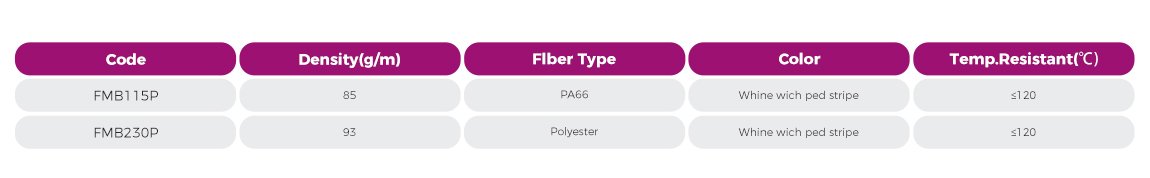

Find The Best Specification For Your Project

Niumaterial Peel Ply for fiberglass shipbuilding materials are available in a variety of gauges, enabling you to precisely match your project

ensuring optimum performance and meeting your specific needs.

Unique Features Of Peel Ply For Shipbuilding Materials

Niumaterial versatile Peel Ply can meet the needs of your diverse projects, guaranteeing superior performance and cost-effectiveness.

Peel Ply creates a textured surface on composite laminates, promoting superior adhesion between layers. This enhanced bonding surface contributes to increased strength and durability of the composite structure.

The unique characteristics of Peel Ply facilitate the removal of excess resin during the curing process. This not only helps in controlling resin content but also results in a clean, smooth surface finish. This prepared surface is ready for additional finishing steps such as painting or bonding.

Peel Ply is designed to be easily peeled away from the cured composite without leaving any residues. This ease of removal simplifies post-processing tasks and ensures that the final product is free from any unwanted fibers or textures, saving time and effort in the production process.

Available in various weights and widths, Peel Ply can be tailored to meet specific project requirements. This customization allows manufacturers to adapt the material to different applications, ensuring flexibility and versatility in composite manufacturing processes.

Peel Ply is highly flexible and stretchable, allowing it to easily conform to complex shapes and contours, ensuring close adhesion to the mold during the forming process. This characteristic makes it suitable for various complex hull structures, such as hulls, decks, and internal components.

Peel Ply is available in multiple thicknesses and material options, meeting the needs of various processes and applications. Customers can choose the most suitable specifications based on their specific requirements, such as 0.5mm thickness Peel Ply for most composite molding processes.

Customized To Your

Unique Needs

Niumaterial understands that every project and application is unique, turning your vision into reality with tailor-made fiberglass shipbuilding materials Peel Ply solutions.

Product Solutions

For traders, Niumaterial will provide you with complete product solutions.

For manufacturers, we will recommend specifications suitable for your project, Provide technical parameters, etc.

Product Customization

Niumaterial offer a range of product customization options to ensure our products meet your specific needs.

Including fiber length, sizing compatibility,special specification customization, etc.

Packaging Customization

Whether you need carton packaging, woven packaging, tube packaging, tray packaging.

Or other additional custom packaging (special labels, branding, etc.)

Free Sample Test

Niumaterial can provide you with free samples for testing, and you can accurately detect in your own environment whether our products are suitable for your project needs.

Join Niumaterial Customer Group

From North America to Europe, from Asia to Africa, and even further afield, Niumaterial shipbuilding materials has entered diversified markets.

Niumaterial Fiberglass

shipbuilding materials

Niumaterial is a professional Shipbuilding Material enterprise with more than 20 years of experience. It has efficient production equipment, high processing precision and assembly technology. It mainly produces and sells Vacuum infuion products tools,fiberglass woven roving, fiberglass chopped strand mat etc.

The Impact Of Trust: Niumaterial Customer Visit

Experience Niumaterial modern factories, professional services and genuine hospitality.

Australia Hull Materials Company

Afghanistan Marine Coatings Supplier

Middle East Marine Composites Manufacturer

United States Marine Fireproofing Contractor

United States Marine Fireproofing Contractor

Marine Repair Materials Supplier in India

Polish Marine Lightweight Materials Trader

Russia Marine Lightweight Materials

Niumaterial Extraordinary Performance At The Exhibition

Build global connections: explore collaborations and tailor solutions for a diverse customer base.

JEC Composites Exhibition

BIG5 Dubai

Canton Fair

Canton Fair

JEC Composites Exhibition

BAU Exhibition

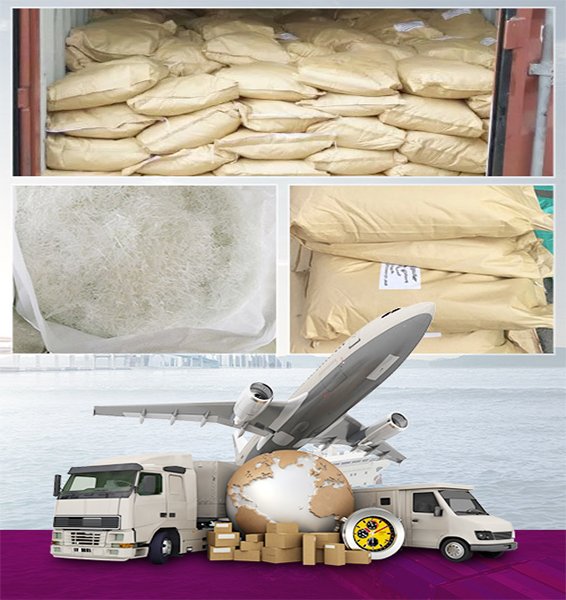

Efficient packaging and shipping solutions

From strict production to safe transportation, Niumaterial guarantees product integrity and timely delivery.

Package

1. Niumaterial fiberglass chopped strands are packed in kraft bags or woven bags, with good moisture resistance, about 25 kg per bag, 4 bags per layer, 8 layers per pallet, 32 bags, and packed with multi-layer shrink film and packing tape. 2. One ton and one bag. 3. 1kg small bag or Naturally soluble packaging Can be customized according to your requirements

Transportation

Niumaterial fiberglass supports multiple shipping methods (sea shipping, air shipping, rail shipping), we can recommend the best shipping method for you.

Delivery Detail

15 days after receiving the deposit.

Listen To Real Customer Feedback

Learn how some of Niumaterial customers have found success with Niumaterial Fiberglass Shipbuilding Material Peel Ply

Frequently Asked Questions About Peel Ply

These Q&A are designed to address the doubts and concerns customers may have when considering doing business with Niumaterial by providing transparent information and timely support.

Peel Ply is mainly used to provide an easily peelable surface during the composite molding process, preventing resin from adhering to the mold and ensuring a smooth, flawless surface after molding.

Yes, Peel Ply is highly flexible and stretchable, allowing it to easily conform to complex shapes and contours, ensuring close adhesion to the mold during the forming process.

Yes, Peel Ply is designed to peel off easily without leaving any residue on the composite surface, ensuring a smooth and perfect finish.

Yes, Peel Ply can be reused multiple times if properly cleaned and maintained. This helps reduce material costs and minimize waste, aligning with environmental requirements.

Niumaterial recommend opting for Western Union, as it offers a more favorable handling fee. However, for new clients, we currently only accept payments through 50% T/T. On the other hand, if you have been a long-standing customer and are experiencing financial constraints, Niumaterial offer the option of OA credit.

It depends on whether you need to customize, if you don't need to customize, Niumaterial can ship within 7 days if we have stock, if you don't have stock and need to customize, it will take 7~15 days!

After delivery, you will generally receive the goods in about 45 days, but the specific time you receive the goods depends on your port, shipping date, customs clearance time and other factors.

Technical Support: Niumaterial team of experts is ready to help you diagnose and resolve any technical issues or challenges you may encounter;

Customer Support: Niumaterial can provide product guidance and advice as well as order tracking and delivery updates according to your specific requirements, ensuring a smooth and hassle-free process from purchase to receipt.

PLACE YOUR ORDER TODAY TO AVAIL ALL THESS BENEFITS!

Free Samples For Testing Your Project!

50+ Fiberglass Product Catalogue!

Product Customization Plan!

Problem Solved Solution!

86-13933702587

infor1@fiberglassyn.com