Rollers Series:

Marine-Grade Durability Solutions

High-Performance Conveyor Components for Shipbuilding Industry: Anti-Corrosion, Lightweight & Longevity

Fiberglass shipbuilding materials Aluminium/Plastic Fluffy Roller

Niumaterial Aluminum/Plastic Roller Series: Core Power Unit for Marine Engineering

The Aluminum/Plastic Roller represents a cutting-edge solution in the realm of material handling, blending the advantageous properties of aluminum and plastic to create a versatile and durable tool. Crafted with precision, this roller caters to the diverse needs of shipbuilding.

The core structure of the roller is forged from high-grade aluminum, capitalizing on its lightweight nature without compromising on strength. This amalgamation makes it an ideal choice for applications where both maneuverability and durability are paramount. The aluminum construction ensures easy transport and handling, allowing users to navigate through diverse work environments with ease.

Aluminium/Plastic Fluffy Roller are used in shipbuilding composites lamination. Aluminium rollers compact fiber layers and remove air (e.g., hull curves, deck cores), while fluffy rollers refine surfaces without fiber damage, optimize resin distribution, reduce voids, and enhance compactness/smoothness, minimizing post-processing.

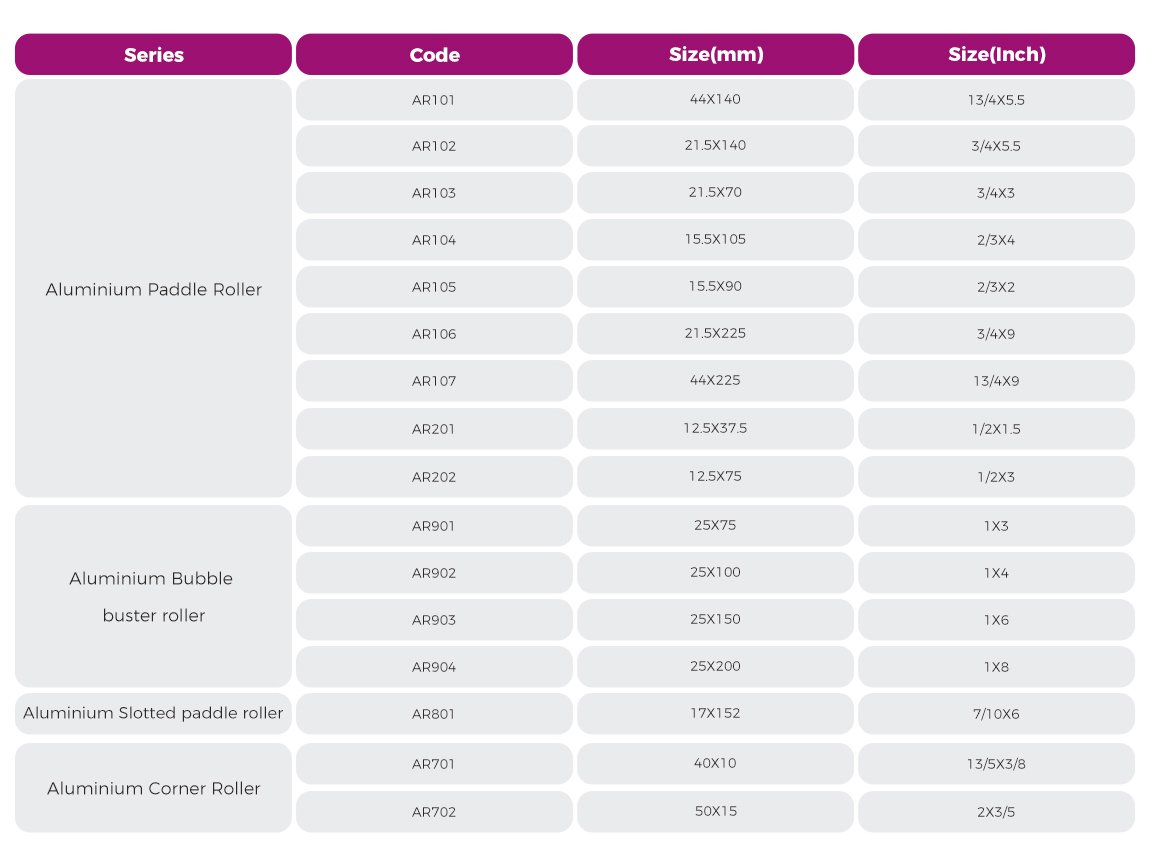

Aluminium Roller

Aluminium Roller series include Aluminium Paddle Roller、Aluminium Paddle Roller、Aluminium Bubble buster roller、Aluminium Slotted paddle roller

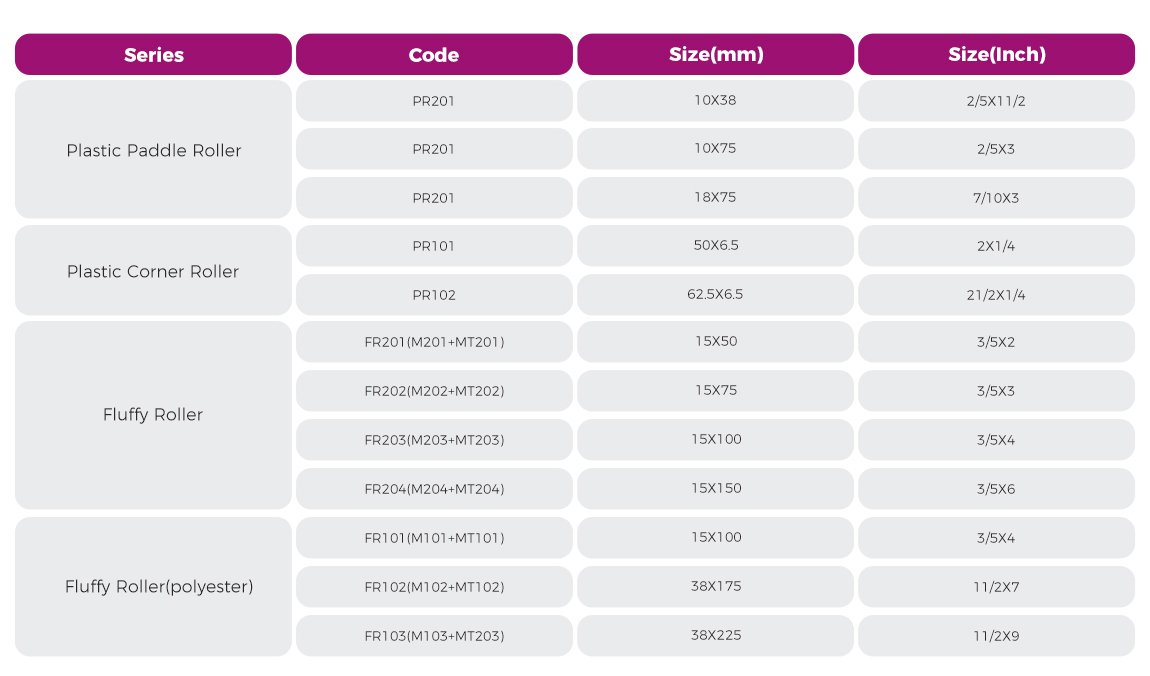

Plastic Fluffy Roller

Plastic Fluffy Roller series include Plastic Paddle Roller、Plastic Corner Roller、Fluffy Roller(wool)、Fluffy Roller(polyester)

Find The Best Specification For Your Project

Niumaterial Aluminium Roller for fiberglass shipbuilding materials are available in a variety of gauges, enabling you to precisely match your project

ensuring optimum performance and meeting your specific needs.

Niumaterial Plastic Fluffy Roller for fiberglass shipbuilding materials are available in a variety of gauges, enabling you to precisely match your project

ensuring optimum performance and meeting your specific needs.

Unique Features Of Aluminum/Plastic Roller For Shipbuilding

Niumaterial versatile Aluminum/Plastic Roller can meet the needs of your diverse projects, guaranteeing superior performance and cost-effectiveness.

Complementing the aluminum frame is the incorporation of high-quality plastic components, strategically placed to enhance the roller’s functionality. The plastic elements contribute to the roller’s resilience and efficiency in material handling. Whether it’s navigating uneven surfaces or smoothly guiding materials down assembly lines, the roller’s design ensures a seamless and reliable performance.

Omega Profile is compatible with vacuum infusion and pre-preg processes, making it a versatile solution for a range of composite manufacturing technologies. This adaptability enables manufacturers to seamlessly integrate resin runners into their existing production processes.

Customized To Your

Unique Needs

Niumaterial understands that every project and application is unique, turning your vision into reality with tailor-made fiberglass shipbuilding materials Aluminum/Plastic Roller solutions.

Product Solutions

For traders, Niumaterial will provide you with complete product solutions.

For manufacturers, we will recommend specifications suitable for your project, Provide technical parameters, etc.

Product Customization

Niumaterial offer a range of product customization options to ensure our products meet your specific needs.

Including fiber length, sizing compatibility,special specification customization, etc.

Packaging Customization

Whether you need carton packaging, woven packaging, tube packaging, tray packaging.

Or other additional custom packaging (special labels, branding, etc.)

Free Sample Test

Niumaterial can provide you with free samples for testing, and you can accurately detect in your own environment whether our products are suitable for your project needs.

Join Niumaterial Customer Group

From North America to Europe, from Asia to Africa, and even further afield, Niumaterial shipbuilding materials has entered diversified markets.

Niumaterial Fiberglass

shipbuilding materials

Niumaterial is a professional Shipbuilding Material enterprise with more than 20 years of experience. It has efficient production equipment, high processing precision and assembly technology. It mainly produces and sells Vacuum infuion products tools,fiberglass woven roving, fiberglass chopped strand mat etc.

The Impact Of Trust: Niumaterial Customer Visit

Experience Niumaterial modern factories, professional services and genuine hospitality.

Australia Hull Materials Company

Afghanistan Marine Coatings Supplier

Middle East Marine Composites Manufacturer

United States Marine Fireproofing Contractor

United States Marine Fireproofing Contractor

Marine Repair Materials Supplier in India

Polish Marine Lightweight Materials Trader

Russia Marine Lightweight Materials

Niumaterial Extraordinary Performance At The Exhibition

Build global connections: explore collaborations and tailor solutions for a diverse customer base.

JEC Composites Exhibition

BIG5 Dubai

Canton Fair

Canton Fair

JEC Composites Exhibition

BAU Exhibition

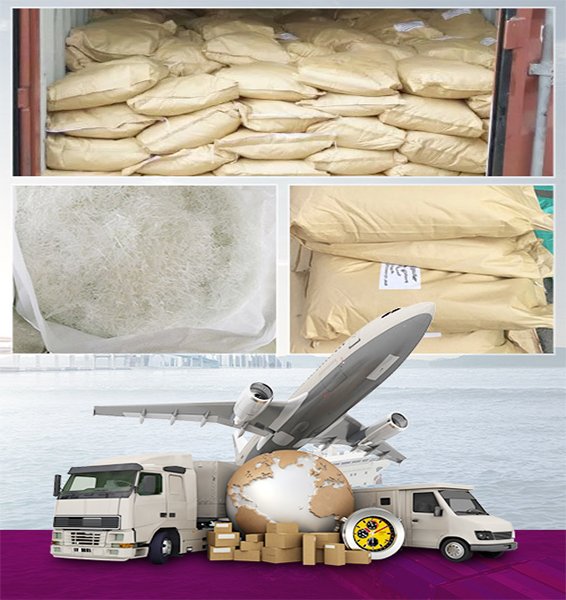

Efficient packaging and shipping solutions

From strict production to safe transportation, Niumaterial guarantees product integrity and timely delivery.

Package

1. Niumaterial fiberglass chopped strands are packed in kraft bags or woven bags, with good moisture resistance, about 25 kg per bag, 4 bags per layer, 8 layers per pallet, 32 bags, and packed with multi-layer shrink film and packing tape. 2. One ton and one bag. 3. 1kg small bag or Naturally soluble packaging Can be customized according to your requirements

Transportation

Niumaterial fiberglass supports multiple shipping methods (sea shipping, air shipping, rail shipping), we can recommend the best shipping method for you.

Delivery Detail

15 days after receiving the deposit.

Listen To Real Customer Feedback

Learn how some of Niumaterial customers have found success with Niumaterial Fiberglass Shipbuilding Material Aluminum/Plastic Roller

Frequently Asked Questions About Aluminum/Plastic Roller

These Q&A are designed to address the doubts and concerns customers may have when considering doing business with Niumaterial by providing transparent information and timely support.

Aluminum Corner Roller (6061-T6) reduces weight by 35% with 2000hrs salt spray resistance, ideal for high-frequency deck operations without rust jamming risks.

Polyester rollers prevent static in cable laying, wool rollers protect delicate instruments. Plastic Corner Roller (Nylon+30% GF) handles -20°C~80°C thermal shocks.

The Aluminum Rollers, such as the Aluminium Corner Roller and Aluminium Paddle Roller, are highly durable due to their robust construction and resistance to wear. They can withstand heavy usage and harsh environments commonly found in shipbuilding. The Plastic Rollers, including the Plastic Paddle Roller and Plastic Corner Roller, are also designed for durability. They are resistant to corrosion and can handle repetitive use without significant degradation.

The Aluminium Corner Roller is ideal for guiding materials around corners, providing smooth transitions and reducing friction. The Aluminium Paddle Roller is used for cutting bubbles in materials, ensuring precise and clean cuts. The Aluminium Bubble Buster Roller is designed to eliminate air bubbles from materials, while the Aluminium Slotted Paddle Roller is perfect for handling materials with slots. The Plastic Rollers, such as the Plastic Paddle Roller and Plastic Corner Roller, are suitable for general material handling and guiding in less demanding environments. The Fluffy Rollers, including the wool and polyester versions, are used for delicate materials that require gentle handling to avoid damage.

Niumaterial recommends choosing Western Union because of its more favorable handling fee. However, for new customers, we currently only accept 50% T/T payment. On the other hand, if you are a long-term customer and funds are tight, Niumaterial offers OA credit options.

It depends on whether you need customization. If not, Niumaterial can ship within 7 days if it has stock. If it does not have stock and needs customization, it will take 7 to 15 days!

Generally, you can receive the goods in about 45 days after shipment, but the specific delivery time depends on your port, shipping date, customs clearance time and other factors.

Technical Support: Niumaterial’s team of experts is ready to help you diagnose and resolve any technical issues or challenges you may encounter;

Customer Support: Niumaterial can provide product guidance and advice based on your specific requirements as well as order tracking and delivery updates, ensuring a smooth and hassle-free process from purchase to delivery.

PLACE YOUR ORDER TODAY TO AVAIL ALL THESS BENEFITS!

Free Samples For Testing Your Project!

50+ Fiberglass Product Catalogue!

Product Customization Plan!

Problem Solved Solution!

86-13933702587

infor1@fiberglassyn.com