Precision Control Pioneer

for Marine Composite Processes

Valve Polypropylene Standard Saddle Clamp Infusion Valve

Fiberglass shipbuilding materials Infusion Valve

Niumaterial Pro-Vac Infusion Valve energy-saving cast steel stainless steel internal thread thermostatically adjustable

The Infusion Valve stands as a pivotal component within the realm of advanced manufacturing processes, specifically tailored for controlling the precise flow of resin in both vacuum infusion and prepreg applications. In the intricate dance of composite material fabrication, where precision and control are paramount, the Infusion Valve emerges as a technological linchpin, facilitating an optimal resin infusion environment.

Similarly, in prepreg processes, where resin is already impregnated into the reinforcement material, the Infusion Valve serves as a gatekeeper, managing the resin flow during subsequent stages of fabrication. By precisely adjusting the valve, manufacturers can tailor the resin infusion to meet the specific requirements of each part, whether it be an aerospace component demanding lightweight strength or a high-performance automotive part requiring resilience under extreme conditions.

Infusion Valve is used in shipbuilding vacuum infusion to control resin flow direction and vacuum pressure, preventing backflow or resin stagnation. Critical for complex structures (e.g., curved hulls, thick deck cores, multi-chamber bulkheads), it ensures uniform resin saturation, eliminates bubbles/dry spots, and enhances efficiency/reliability in large composite manufacturing.

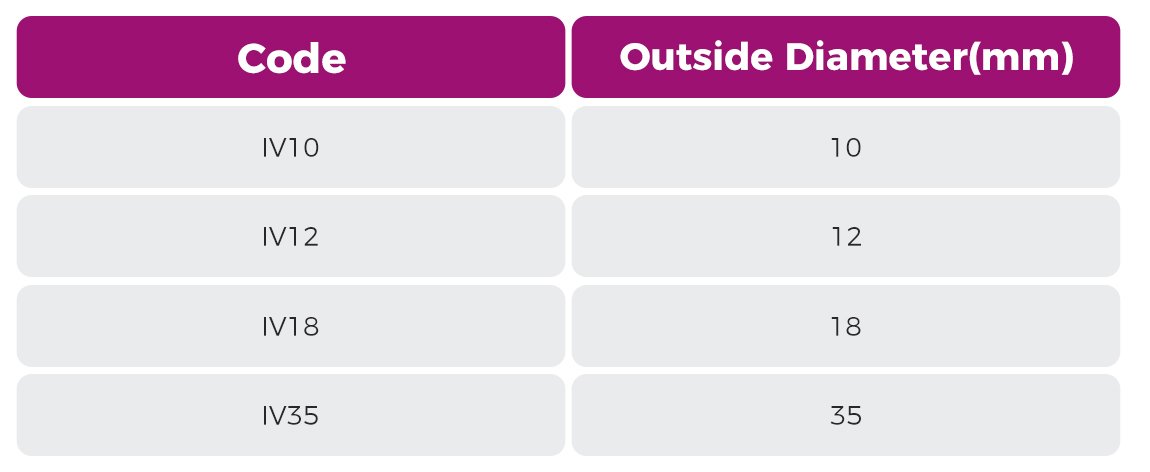

Find The Best Specification For Your Project

Niumaterial Infusion Valve for fiberglass shipbuilding materials are available in a variety of gauges, enabling you to precisely match your project

ensuring optimum performance and meeting your specific needs.

Unique Features Of Infusion Valve For Shipbuilding Materials

Niumaterial versatile Infusion Valve can meet the needs of your diverse projects, guaranteeing superior performance and cost-effectiveness.

One of the notable features of the Infusion Valve is its adaptability to a wide range of resin viscosities. This flexibility allows manufacturers to work with different types of resins, adjusting the valve settings to accommodate specific material properties. Whether dealing with low-viscosity or high-viscosity resins, the Infusion Valve provides a versatile solution for diverse manufacturing requirements.

The Infusion Valve plays a crucial role in optimizing resin usage, preventing overconsumption during the manufacturing process. By efficiently controlling the resin flow, it minimizes waste, contributing to both cost savings and environmental sustainability. Manufacturers can achieve a balance between material efficiency and product quality, enhancing the overall economic viability of composite production.

Designed to meet the demands of different composite manufacturing scenarios, the Infusion Valve boasts a high level of compatibility with various processing environments. Its robust design and adjustable settings make it suitable for integration into different production setups, ensuring that manufacturers can deploy this technology across a spectrum of applications without compromising performance.

Customized To Your

Unique Needs

Niumaterial understands that every project and application is unique, turning your vision into reality with tailor-made fiberglass shipbuilding materials Infusion Valve solutions.

Product Solutions

For traders, Niumaterial will provide you with complete product solutions.

For manufacturers, we will recommend specifications suitable for your project, Provide technical parameters, etc.

Product Customization

Niumaterial offer a range of product customization options to ensure our products meet your specific needs.

Including fiber length, sizing compatibility,special specification customization, etc.

Packaging Customization

Whether you need carton packaging, woven packaging, tube packaging, tray packaging.

Or other additional custom packaging (special labels, branding, etc.)

Free Sample Test

Niumaterial can provide you with free samples for testing, and you can accurately detect in your own environment whether our products are suitable for your project needs.

Join Niumaterial Customer Group

From North America to Europe, from Asia to Africa, and even further afield, Niumaterial shipbuilding materials has entered diversified markets.

Niumaterial Fiberglass

shipbuilding materials

Niumaterial is a professional Shipbuilding Material enterprise with more than 20 years of experience. It has efficient production equipment, high processing precision and assembly technology. It mainly produces and sells Vacuum infuion products tools,fiberglass woven roving, fiberglass chopped strand mat etc.

The Impact Of Trust: Niumaterial Customer Visit

Experience Niumaterial modern factories, professional services and genuine hospitality.

Australia Hull Materials Company

Afghanistan Marine Coatings Supplier

Middle East Marine Composites Manufacturer

United States Marine Fireproofing Contractor

United States Marine Fireproofing Contractor

Marine Repair Materials Supplier in India

Polish Marine Lightweight Materials Trader

Russia Marine Lightweight Materials

Niumaterial Extraordinary Performance At The Exhibition

Build global connections: explore collaborations and tailor solutions for a diverse customer base.

JEC Composites Exhibition

BIG5 Dubai

Canton Fair

Canton Fair

JEC Composites Exhibition

BAU Exhibition

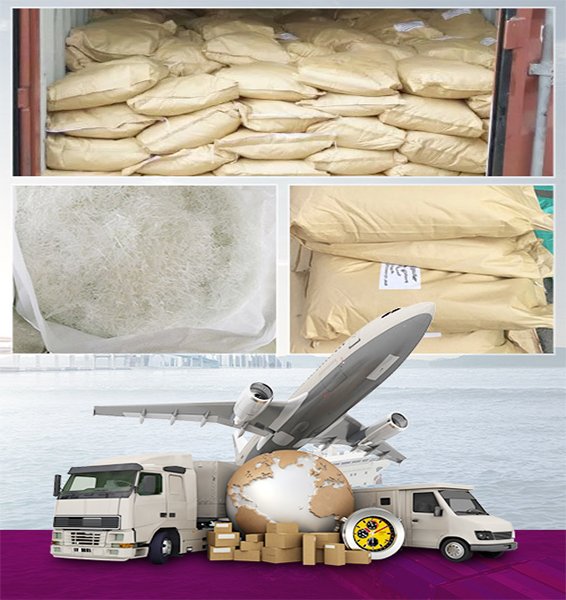

Efficient packaging and shipping solutions

From strict production to safe transportation, Niumaterial guarantees product integrity and timely delivery.

Package

1. Niumaterial fiberglass chopped strands are packed in kraft bags or woven bags, with good moisture resistance, about 25 kg per bag, 4 bags per layer, 8 layers per pallet, 32 bags, and packed with multi-layer shrink film and packing tape. 2. One ton and one bag. 3. 1kg small bag or Naturally soluble packaging Can be customized according to your requirements

Transportation

Niumaterial fiberglass supports multiple shipping methods (sea shipping, air shipping, rail shipping), we can recommend the best shipping method for you.

Delivery Detail

15 days after receiving the deposit.

Listen To Real Customer Feedback

Learn how some of Niumaterial customers have found success with Niumaterial Fiberglass Shipbuilding Material Infusion Valve

Frequently Asked Questions About Infusion Valve

These Q&A are designed to address the doubts and concerns customers may have when considering doing business with Niumaterial by providing transparent information and timely support.

Infusion Valve is primarily used in the resin vacuum infusion process of shipbuilding, suitable for infusing various hull structural components, decks, bulkheads, and other parts of different sizes and shapes. It ensures uniform resin distribution in a vacuum environment, improving product quality and production efficiency.

Infusion Valve can achieve high-precision flow control with an accuracy range of ±5%. This precise flow control ensures uniform resin distribution during the infusion process, reducing waste and improving product quality.

Infusion Valve uses advanced sealing technology to achieve high-efficiency vacuum sealing, ensuring no air leaks during the infusion process. Its sealing performance has been strictly tested and meets international standards, ensuring the stability and reliability of the infusion process.

Yes, Niumateria offers customization services for Infusion Valve, allowing adjustments in size, shape, and performance parameters based on specific customer requirements to meet unique project needs.

Niumaterial recommend opting for Western Union, as it offers a more favorable handling fee. However, for new clients, we currently only accept payments through 50% T/T. On the other hand, if you have been a long-standing customer and are experiencing financial constraints, Niumaterial offer the option of OA credit.

It depends on whether you need to customize, if you don't need to customize, Niumaterial can ship within 7 days if we have stock, if you don't have stock and need to customize, it will take 7~15 days!

After delivery, you will generally receive the goods in about 45 days, but the specific time you receive the goods depends on your port, shipping date, customs clearance time and other factors.

Technical Support: Niumaterial team of experts is ready to help you diagnose and resolve any technical issues or challenges you may encounter;

Customer Support: Niumaterial can provide product guidance and advice as well as order tracking and delivery updates according to your specific requirements, ensuring a smooth and hassle-free process from purchase to receipt.

PLACE YOUR ORDER TODAY TO AVAIL ALL THESS BENEFITS!

Free Samples For Testing Your Project!

50+ Fiberglass Product Catalogue!

Product Customization Plan!

Problem Solved Solution!

86-13933702587

infor1@fiberglassyn.com