In the modern construction industry, gypsum board is widely used in the construction of walls, ceilings and partitions as a lightweight, efficient and cost-effective building material. As the construction industry continues to increase its requirements for material performance, manufacturers are constantly looking for innovative ways to improve product quality. Glass fiber reinforced materials, especially SMC (Sheet Molding Compound)roving, have become an ideal choice for gypsum board manufacturing due to its excellent mechanical properties and adaptability. This article will explore the application and advantages of SMC roving in gypsum board manufacturing and introduce the SMC roving products provided by Niumaterial.

Gypsum board is a composite board composed of calcium sulfate dihydrate (CaSO4·2H2O), which is usually made through mixing, molding, drying and other processes. Although gypsum itself has good fire resistance and sound insulation, its brittleness limits its use in certain application scenarios. To overcome this disadvantage, adding reinforcing materials such as glass fiber becomes essential. Fiberglass SMC roving has proven to be an ideal choice for gypsum board reinforcement with its high strength, low weight and good processing properties1. It can not only significantly improve the flexural strength and impact resistance of the board, but also improve dimensional stability and surface quality.

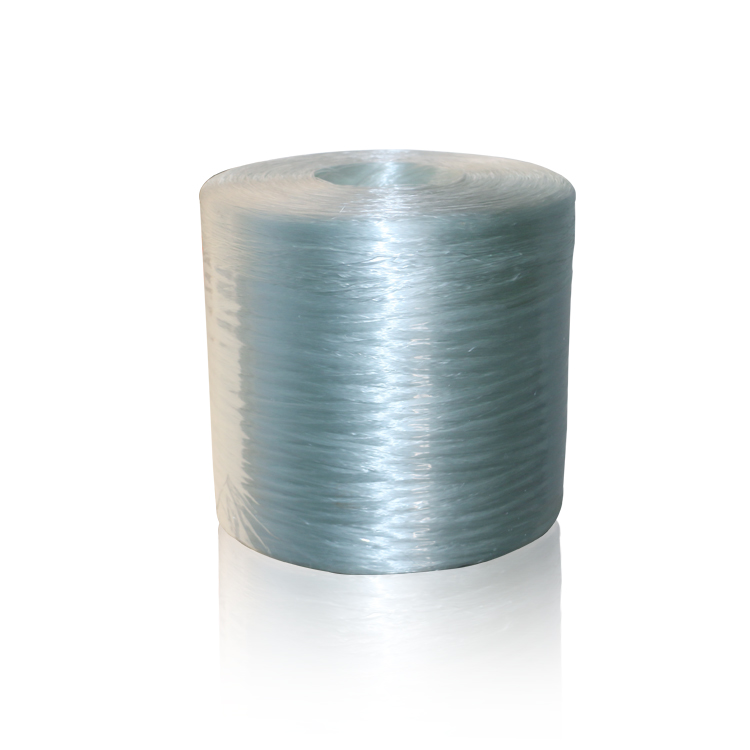

SMC roving is mainly divided into two types: direct roving and pliedroving6. Direct roving is suitable for application scenarios that require high tensile strength, while plied roving is more suitable for processes that require good dispersion. In gypsum board manufacturing, direct roving is often used to provide core structural support, while plied roving is used to increase the overall toughness and uniformity of the board. Depending on the specific product specifications and performance requirements, manufacturers can choose the appropriate SMC roving type for optimal configuration.

The main component of SMC roving is glass fiber, which is a synthetic fiber based on silicate. Glass fiber has excellent mechanical properties, including high strength, low density and excellent chemical stability. After adding SMC roving to gypsum board, it can not only enhance the physical properties of the board, but also effectively reduce moisture absorption and improve durability. In addition, due to the low thermal conductivity of glass fiber, it can also help improve the thermal insulation performance of gypsum board5.

A typical example is the high-performance gypsum board used in high-end residential and commercial buildings. These boards are usually required to meet higher fire protection standards and structural strength requirements. By adopting gypsum board containing SMC roving, not only can the above requirements be met, but also the ease of operation during construction and the aesthetics of the final product can be ensured. For example, in some large public facility projects, after using gypsum board containing SMC roving, the maintenance cost of the building has been greatly reduced, while the overall safety level has been improved.

When choosing the right glass fiber reinforcement material, the following factors should be considered:

Different application scenarios have different requirements for the performance of gypsum board.

Consider the influence of factors such as temperature and humidity.

Balance the relationship between performance and budget.

It is recommended to cooperate with professional suppliers, such as Niumaterial, who can provide customized solutions according to your specific needs.

Niumaterial is committed to providing high-quality SMC roving fiberglass products, whose product features include but are not limited to:

In short, SMC roving, as a key reinforcing material in gypsum board manufacturing, plays an irreplaceable role in improving the performance of the board. It is an important part of achieving high-quality building solutions, both from a technical and market perspective. By reasonably selecting SMC roving, especially products from high-quality suppliers like Niumaterial, it can ensure that gypsum board performs well in various application environments and meets the needs of modern construction. I hope this article can provide you with a comprehensive understanding of SMC roving in gypsum board manufacturing and help you make a wise choice.

If you have any questions

Please contact us for free consultation and product quotation

Table of Contents Add a h

Table of Contents Add a h