The shipbuilding industry is at a crossroads. As global demand for lightweight, corrosion-resistant, and high-performance vessels surges, manufacturers are racing to adopt materials and processes that balance cost, speed, and quality. Traditional methods, while reliable, often struggle to meet modern expectations for efficiency and sustainability. Enter fiberglass spray up roving—a game-changing material that has transformed how ships are designed, built, and maintained. At Niumaterial, we’re not just keeping pace with this revolution; we’re leading it.

For over two decades, Niumaterial has cemented its reputation as a premier fiberglass spray up roving manufacturer, supplier, and factory innovator. Our commitment to precision engineering, cutting-edge technology, and customer-centric solutions has made us the go-to partner for shipbuilders worldwide. Whether crafting sleek yachts, rugged fishing trawlers, or high-speed patrol boats, our spray up roving products deliver unmatched strength-to-weight ratios, seamless application, and long-term durability.

But what exactly makes fiberglass spray up roving the backbone of modern shipbuilding? Why are leading shipyards switching to Niumaterial’s solutions? In this article, we’ll dive deep into the science, process, and real-world impact of this material—and reveal how partnering with a trusted spray up roving manufacturer like Niumaterial can elevate your projects from ordinary to extraordinary.

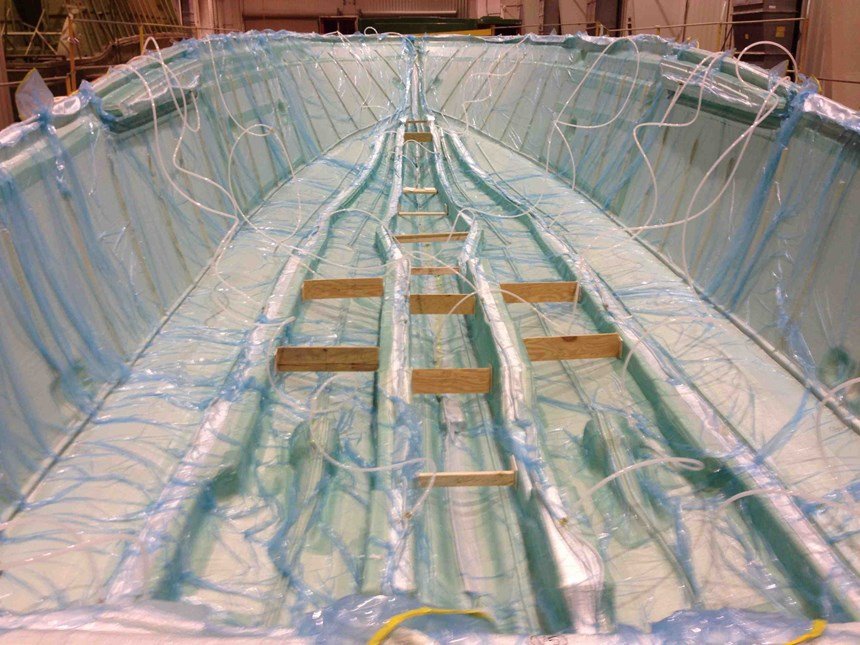

Fiberglass spray up roving is a composite material made from continuous strands of glass fibers bundled into rovings. These rovings are specifically engineered for spray-up applications, where they’re combined with resin and catalysts using specialized equipment. The result? A lightweight, high-strength material that conforms effortlessly to complex shapes—perfect for crafting hulls, decks, and structural components.

At Niumaterial, our roving isn’t just “standard.” As a fiberglass spray up roving supplier, we optimize fiber sizing, strand integrity, and compatibility with resins to ensure superior adhesion, reduced waste, and faster curing times.

The spray-up process involves three key steps:

Chopping and Spraying: Roving is fed into a chopper gun, which cuts the fibers into predetermined lengths and sprays them onto a mold alongside resin.

Layering: Operators build thickness by applying multiple layers, adjusting fiber orientation for optimal strength.

Curing: The composite cures under controlled conditions, forming a rigid, seamless structure.

Niumaterial’s expertise as a spray up roving factory ensures our products are tailored for this workflow. Our rovings minimize clogging in equipment, reduce resin consumption by 15%, and accelerate production cycles by up to 20% compared to competitors.

From hulls to bulkheads, spray up roving is the secret behind vessels that withstand harsh marine environments. Its applications include:

Hull Construction: Creates watertight, impact-resistant layers.

Deck Panels: Delivers non-slip surfaces with minimal weight.

Internal Structures: Reinforces compartments without adding bulk.

Case in point: A leading Asian shipyard reduced hull production time by 30% after switching to Niumaterial’s roving, citing improved fiber-resin bonding and fewer defects.

In the context of shipbuilding, spray-up fiberglass roving provides a lightweight, strong, and durable material that can significantly enhance the performance and longevity of the vessel.

As a fiberglass spray up roving factory with ISO 9001 certification, we combine scale with specialization. Our facilities produce over 50,000 metric tons annually, yet every batch undergoes rigorous QA testing. Key advantages include:

Custom Fiber Sizing: Tailored for epoxy, polyester, or vinyl ester resins.

Low Fuzz Technology: Reduces airborne particles, improving worker safety.

Eco-Friendly Formulations: 30% recycled glass content without compromising strength.

Case Study 1: A European luxury yacht builder achieved a 50% reduction in hull repair claims by using Niumaterial’s roving, thanks to its exceptional fatigue resistance.

Case Study 2: A Middle Eastern contractor cut vessel weight by 12% while maintaining MIL-SPEC compliance, enabling higher speeds and fuel savings.

Tensile Strength: 15% higher than industry averages (3,500 MPa vs. 3,000 MPa).

Corrosion Resistance: 10-year salt spray tests show zero delamination.

ROI: Clients report payback periods under 6 months due to reduced downtime and waste.

Roving refers to bundles of untwisted glass fibers. Unlike woven fabrics, roving allows for multidirectional strength and rapid application. Niumaterial’s proprietary treatments enhance UV resistance and chemical stability, critical for saltwater exposure.

The future of shipbuilding lies in smarter materials—and Niumaterial is at the helm. As a global spray up roving manufacturer and supplier, we don’t just sell products; we deliver partnerships. From R&D support to just-in-time logistics, our team ensures your projects stay on budget, on spec, and ahead of the curve.

Ready to transform your shipbuilding process? Contact Niumaterial today and discover why industry leaders trust us to navigate the toughest challenges on the water.

If you have any questions

Please contact us for free consultation and product quotation

Table of Contents Add a h

Table of Contents Add a h