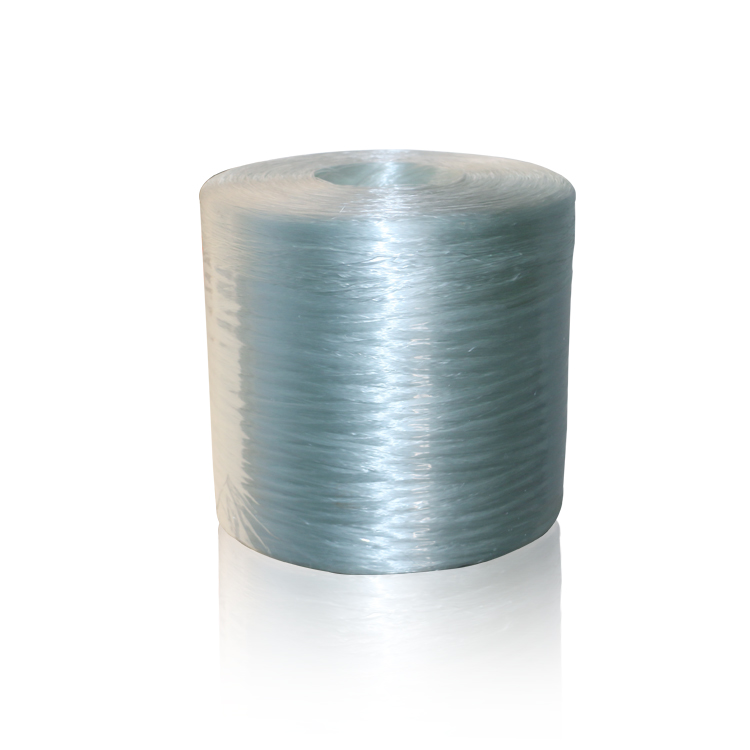

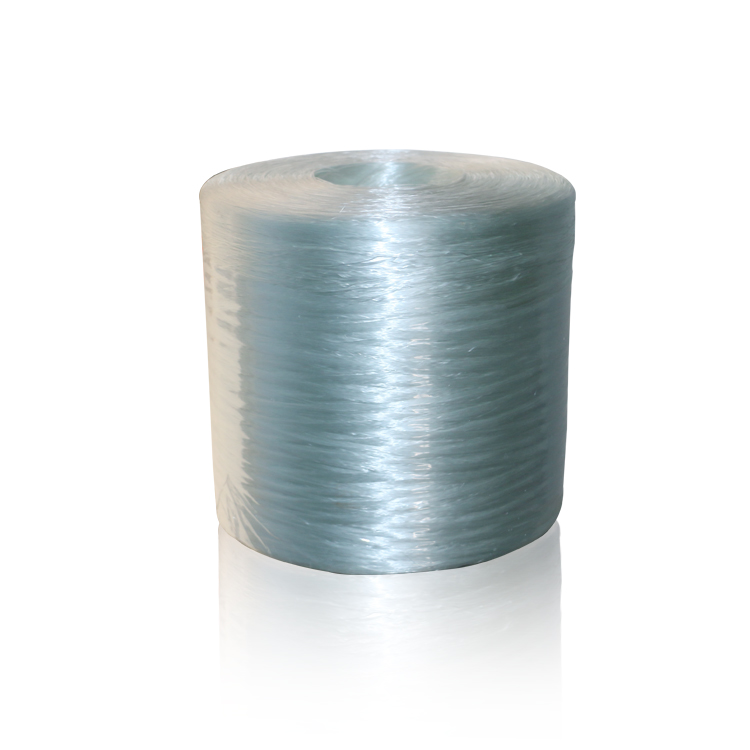

In modern industry and construction, choosing the right reinforcement material is crucial to ensure the success of the project. As a high-performance composite material, glass fiber SMC (Sheet Molding Compound) roving has gradually become the material of choice in many fields due to its excellent mechanical properties and wide applicability. This article will explore in depth why glass fiber SMC roving is chosen instead of traditional materials, analyze its similarities and differences with gypsum roving, and introduce in detail the application scenarios, selection criteria and high-quality products provided by Niumaterial.

Glass fiber SMC roving has significant advantages over traditional materials. The following are its main features:

Fiberglass SMC roving is known for its excellent tensile strength and low density. This allows it to significantly improve the overall strength and rigidity of the material without adding too much weight. For example, in automobile manufacturing, the use of SMC roving can reduce the weight of the car body, thereby improving fuel efficiency and driving performance.

Glass fiber has good high temperature resistance and can maintain its physical properties unchanged under extreme temperatures. In addition, glass fiber also has excellent chemical stability and can resist corrosion in most acid and alkali environments, making it suitable for chemical equipment, marine engineering and other fields.

SMC roving is usually pre-impregnated with resin or adhesive, which is convenient for direct laying and molding. This pretreatment method not only improves construction efficiency, but also reduces the complexity and time cost of on-site operations. Especially in large-scale engineering projects, an efficient construction process is the key to ensuring that the project is completed on time.

Glass fiber SMC roving has good weather resistance and can resist the influence of natural environment such as ultraviolet radiation, wind and rain erosion. Whether in outdoor buildings or infrastructure exposed to harsh weather conditions for a long time, SMC roving can maintain long-term stability and beauty.

Although SMC roving and gypsum roving are both widely used in the field of building materials, they have significant differences in materials and applications:

Glass fiber SMC roving is widely used in many industries due to its excellent performance:

When choosing the SMC roving that best suits your project, consider the following factors

Clarify the project requirements, such as whether high strength, lightweight, high temperature resistance or corrosion resistance are required.

Understand the specific requirements of different application scenarios and choose the corresponding SMC roving type.

Technical parameters such as tensile strength, modulus, and elongation at break are important indicators for evaluating SMC roving.

Choose products with corresponding physical properties according to the needs of specific projects.

Processing properties such as wettability, bunching, and spreadability determine the difficulty of construction.

Choose SMC roving that is easy to construct and can ensure high-quality molding.

Balance the initial investment and long-term use costs, and choose products with high cost performance.

Comprehensively consider material prices, construction costs, and maintenance costs.

Niumaterial is committed to providing high-quality glass fiber SMC roving, and its product advantages include but are not limited to

Niumaterial SMC roving adopts advanced production technology to ensure that each fiber has extremely high tensile strength and fatigue resistance, which can significantly improve the overall strength and durability of the product.

This feature makes it easier for SMC roving to combine with the substrate during the production process, forming a uniformly distributed reinforcement structure, improving the processing performance and surface quality of the board.

All Niumaterial products have passed strict ISO certification and other international standard certifications. Choosing us means choosing the guarantee of quality and safety.

Niumaterial has a professional technical team that can provide customers with a full range of services from material selection consultation to production process guidance. Whether it is a problem encountered in the product development stage or in the production process, it can be solved promptly and effectively.

Niumaterial has provided customized solutions for many well-known companies and achieved remarkable results. These successful cases demonstrate our product and technical strength and enhance customer confidence.

In summary, glass fiber SMC roving has become an ideal choice for many industries due to its excellent characteristics such as high strength, light weight, high temperature resistance and corrosion resistance. By clarifying the project requirements, evaluating the physical properties and processing performance, and balancing the cost-effectiveness, you can choose the most suitable SMC roving for your project. As a trustworthy supplier, Niumaterial not only provides high-quality products, but also provides comprehensive technical support and service guarantees to help you achieve the success of your project. I hope this article can provide you with valuable reference and help you make a wise choice.

If you have any questions

Please contact us for free consultation and product quotation

Table of Contents Add a h

Table of Contents Add a h