With the advancement of technology and the increase in environmental awareness, the automotive industry is undergoing unprecedented changes. The application of lightweight, high-performance materials has become the key to improving vehicle performance and energy efficiency. As a high-strength, low-density advanced material, fiberglass plays an increasingly important role in automobile manufacturing. This article will explore in depth why fiberglass is important to the automotive industry, introduce different types of fiberglass and their characteristics in detail, analyze their applications in different components, and ultimately help you choose the type of fiberglass that is most suitable for the automotive industry.

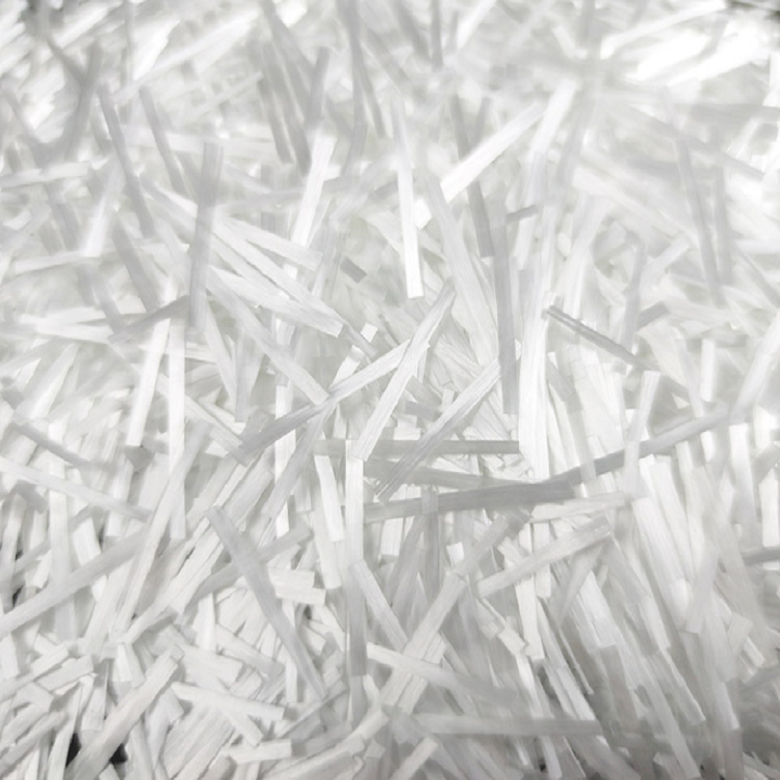

Glass fiber composites (GFRP) have an extremely high strength-to-weight ratio and can significantly reduce the weight of the vehicle body while maintaining or even improving structural strength. This is essential for improving fuel efficiency, reducing emissions and improving acceleration performance. Studies have shown that every 10% reduction in vehicle weight can reduce fuel consumption by 6-8%.

Fiberglass is not only lightweight, but also has excellent impact resistance. It can absorb a lot of energy in a collision and protect the safety of passengers. In addition, glass fiber composites can also disperse stress through optimized design, further improving the safety of the entire vehicle.

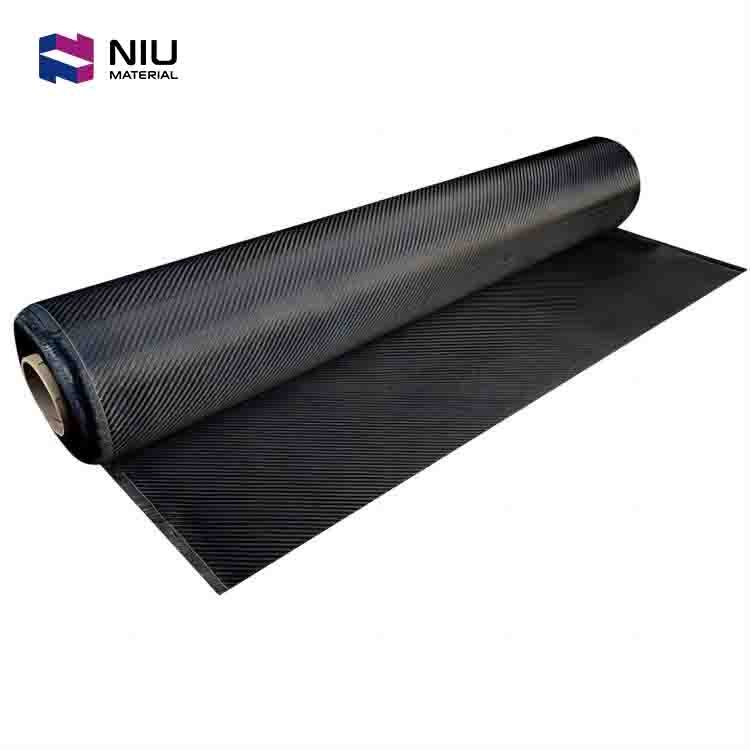

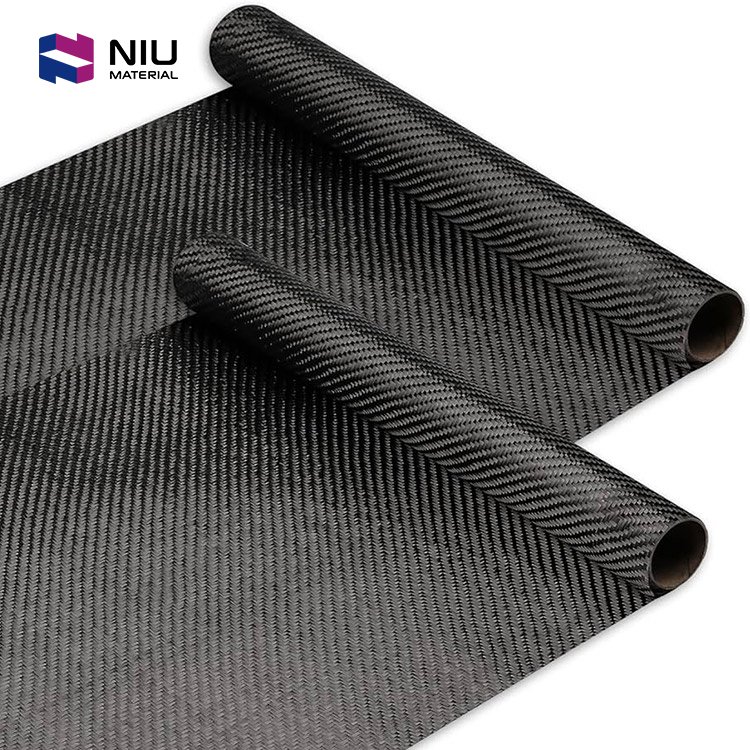

The unique woven texture of glass fiber gives the interior and exterior of the car a more stylish and high-end feel. Many high-end models use glass fiber trims to highlight their luxury and technical content and meet consumers’ demand for personalization.

First, evaluate the specific needs of the project, including the application environment, structural requirements, and construction conditions. Understanding the characteristics and requirements of the project will help choose the most suitable type of glass fiber.

Second, consider the properties of glass fiber, such as tensile strength, corrosion resistance, flexibility, and crack resistance. According to the specific needs of the project, choose the type of glass fiber with the best performance.

Finally, refer to industry standards and specifications to ensure that the selected materials meet the relevant requirements. Cooperate with professional suppliers to get more technical support and suggestions to ensure the smooth implementation of the project.

Niumaterial strictly follows international quality standards to ensure that each batch of products reaches the highest level. The company has passed a number of certifications, including ISO 9001 quality management system certification, ASTM D3039 composite material tensile performance test standard and EN 13501-1 fire performance test standard. High-quality products ensure the successful implementation of customer projects.

With more than 20 years of technical accumulation and market experience, niumaterial is well aware of customer needs and can provide the most suitable solutions. It provides more than 1,000 tons of procurement services to more than 100 companies around the world each year, which are widely used in automobiles, aviation, sports and other fields. Rich experience enables niumaterial to respond quickly to market demand and provide efficient services.

Niumaterial has a professional technical team that can provide comprehensive technical support during the design, production and installation process to ensure that customers can fully utilize the advantages of the product. In addition, the company also provides perfect after-sales service to solve the problems encountered by customers in a timely manner and ensure the long-term stable operation of the project. Comprehensive customer service enables customers to choose niumaterial’s products with confidence.

Niumaterial always pays attention to the development of the industry and continuously introduces new technologies and new materials to improve the performance and efficiency of products. The company cooperates with many well-known universities and research institutions to jointly develop new materials and new technologies to ensure that the products always maintain the leading position in the industry. Innovation and technological progress give niumaterial’s products a clear competitive advantage in the market.

Niumaterial is committed to reducing VOC emissions in the production process and adopting environmentally friendly materials to meet international environmental standards. The company has reduced energy consumption by 30% in the production process, further reducing its carbon footprint. The concept of environmental protection and sustainability makes niumaterial not only pay attention to product quality, but also pay attention to environmental protection and social responsibility.

In summary, glass fiber, as a high-performance advanced material, plays an important role in automobile manufacturing. Different types of glass fiber have their own characteristics and advantages and are suitable for different application scenarios. To choose the most suitable type of glass fiber for the automotive field, it is necessary to comprehensively consider the application environment, structural requirements and construction conditions. I hope this article can provide you with valuable reference and help you make a wise choice. If you have any needs or questions about fiberglass, please feel free to contact us, we will serve you wholeheartedly!

In the future, fiberglass will continue to play an important role in automobile manufacturing and promote the development and progress of the industry. Whether it is a traditional fuel vehicle or a new energy vehicle, fiberglass is your ideal choice to improve performance and energy efficiency. Choose niumaterial carbon fiber cloth woven to ensure the success of your project!

If you have any questions

Please contact us for free consultation and product quotation

Table of Contents Add a h

Table of Contents Add a h