In modern industry and construction, needle felt, as a high-performance fiber material, is widely used in multiple industries due to its excellent physical and chemical properties. This article will explore in depth the different types of needle felt, its manufacturing materials, and its applications in different industries. Finally, we will introduce in detail why Niumaterial needle felt is the best choice.

Fiberglass needle felt is a non-woven fabric formed by fixing randomly distributed fibers together through a mechanical needle punching process. It has many advantages such as light weight, high strength, high temperature resistance, and corrosion resistance. It is widely used in filtration, insulation, sound insulation and other fields. The production process of needle felt mainly includes fiber arrangement, needle punching process and post-treatment methods. These steps give needle felt unique properties and the possibility of wide application.

High silica needle mat is made of high silica fiber, has extremely high temperature resistance, and can remain stable in extreme environments. It not only has excellent thermal insulation performance, but also has good tear resistance and flexibility.

High temperature pipe insulation: Suitable for insulation in high temperature environments such as industrial furnaces and steam pipes.

Fire barrier: used as fire barrier inside buildings to slow down the spread of fire.

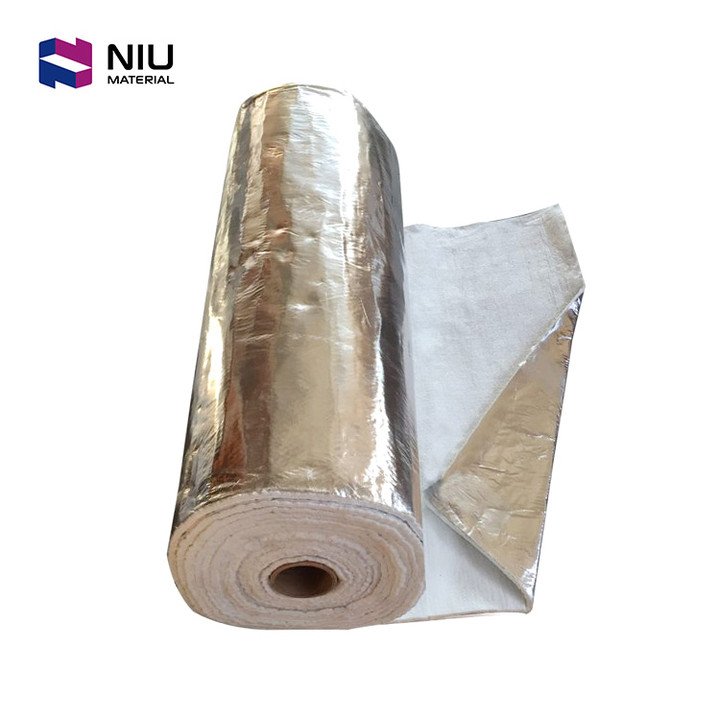

Aluminum foil needle felt is a material with an aluminum foil layer added to the ordinary needle felt, which enhances its ability to reflect heat. This design not only makes the material have excellent thermal insulation performance, but also effectively blocks radiant heat.

High-efficiency insulation: widely used in building exterior wall insulation, roof insulation and other occasions.

Low-temperature pipe protection: used for low-temperature pipe insulation in refrigeration equipment to prevent cold loss.

Aerogel needle felt combines the advantages of aerogel and needle felt, with extremely low thermal conductivity and ultra-light weight. The nano-scale pore structure of aerogel gives the material excellent thermal insulation performance while maintaining the flexibility and easy processing of needle felt.

High-end insulation: suitable for fields with extremely high insulation requirements such as aerospace and precision instruments.

Special environment: used for thermal insulation in extreme environments such as deep-sea detectors and polar research stations.

Alkali-free needle felt is made of alkali-free glass fiber, which has excellent corrosion resistance and is particularly suitable for long-term use in acid and alkali environments. In addition, alkali-free fiber also has good electrical insulation properties and is suitable for the protection of electronic equipment.

Chemical pipeline insulation: used for corrosive pipeline insulation in chemical plants to extend pipeline life.

Power facilities: used for the protection of power facilities such as cable trenches and transformers to improve safety.

The main component of needle felt is glass fiber, but it may also contain other types of fiber materials, such as polyester fiber, quartz fiber, etc. The choice of different materials determines the specific performance and application areas of needle felt.

High-purity quartz fiber: has extremely high temperature resistance and electrical insulation performance, and is suitable for insulation and protection in special fields.

Fiberglass needle mat is widely used in high-temperature or low-temperature pipeline insulation in industries such as petroleum, chemical, and electric power. Its excellent thermal insulation and corrosion resistance make it an indispensable insulation material in these industries. For example, in petrochemical plants, needle felt is used for pipeline insulation for transporting high-temperature media, reducing energy loss and extending pipeline life.

In urban heating systems, needle felt is used for hot water and steam pipeline insulation to reduce heat loss and improve energy efficiency. Its light weight and easy installation also greatly simplify the construction process.

Needle felt is used for low-temperature pipe insulation of refrigeration system to prevent cold loss. Its excellent thermal insulation and waterproof and moisture-proof properties ensure the stable operation of the system.

Needle mat is mainly used for the filter layer of catalytic converter in automobile exhaust treatment system. It can effectively capture particulate matter in exhaust gas and reduce harmful gas emissions. Due to its high temperature and corrosion resistance, needle felt can maintain efficient filtering effect for a long time.

Needle felt is also widely used in automobile mufflers to absorb sound and reduce shock. Its porous structure can absorb noise and provide a quieter driving experience.

Niumaterial strictly follows international quality standards to ensure that each batch of products reaches the highest level. The company has passed a number of certifications, including ISO 9001 quality management system certification, ASTM D3039 composite material tensile performance test standard and EN 13501-1 fire performance test standard.

With more than 20 years of technical accumulation and market experience, Niumaterial is well aware of customer needs and can provide the most suitable solutions. It provides more than 1,000 tons of procurement services to more than 100 companies around the world each year, which are widely used in building reinforcement, pipeline repair and decoration and other fields.

Niumaterial has a professional technical team that can provide comprehensive technical support during the design, production and installation process to ensure that customers can fully utilize the advantages of the product. In addition, the company also provides comprehensive after-sales service to promptly solve the problems encountered by customers and ensure the long-term and stable operation of the project.

In summary, fiberglass needle mat, as a high-performance fiber material, is widely used in many industries due to its excellent physical and chemical properties. Different types of needle felt (such as high silica needle felt, aluminum foil needle felt, aerogel needle felt, alkali-free needle felt) have their own characteristics and are suitable for different application scenarios. In particular, Niumaterial needle felt, with its excellent quality, rich industry experience and comprehensive customer service, can provide you with the most reliable solutions. Choosing Niumaterial needle felt can not only improve the performance of the product, but also extend the service life, reduce maintenance costs, and improve the safety and reliability of the overall system. If you have any needs or questions about needle felt, please feel free to contact us, we will serve you wholeheartedly!

If you have any questions

Please contact us for free consultation and product quotation

Table of Contents Add a h

Table of Contents Add a h