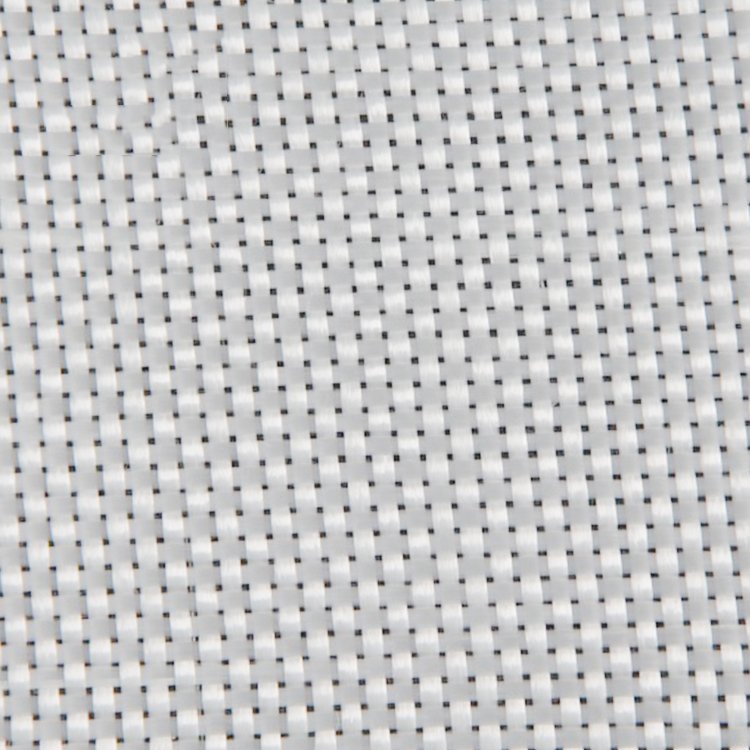

With the advancement of building materials technology, fiberglass products have played an increasingly important role in modern construction and industrial applications due to their excellent performance. Among them, fiberglass mesh and fiberglass woven cloth are two common forms, each with unique characteristics and uses. Fiberglass mesh cloth usually uses a special weaving process to weave glass fiber filaments into a grid shape, thus forming a cloth with high strength and good stability. Woven cloth usually presents a regular square or rectangular grid pattern. This structure makes the woven cloth excellent in mechanical properties.

Fiberglass mesh is a kind of cloth made of glass fiber filaments woven into a grid structure. It is usually made of E-glass fiber as raw material, which is woven after high-temperature drawing and coating. The characteristic of mesh cloth is its open grid structure. This design not only gives the material good air permeability, but also gives it high tensile strength and dimensional stability. Fiberglass mesh is mainly used in the fields of internal and external wall insulation systems, waterproofing projects, floor laying, etc. in the construction industry to enhance the strength of the substrate and prevent cracking.

Fiberglass woven roving is also a kind of fabric woven from glass fiber filaments, but it is different from mesh fabric in the way it is woven. Woven fabric usually adopts plain weave, that is, the warp and weft yarns are arranged one above the other, forming a regular square or rectangular grid. This structure gives the woven fabric better mechanical properties, such as higher tensile strength and shear strength. Fiberglass woven fabric is widely used in the reinforcement of composite materials, such as shipbuilding, automotive parts, sports equipment, etc. It is also commonly used in the production of various industrial protective clothing and fireproof materials.

Material composition: Whether it is fiberglass mesh or gingham, the basic material is glass fiber. This fiber is usually drawn from molten glass with silica as the main component. In order to improve certain properties, such as alkali resistance or mechanical strength, a small amount of other ingredients such as aluminum oxide and calcium oxide are sometimes added to the formula.

Manufacturing process:

Mesh cloth manufacturing: First, the glass is melted and drawn into filaments through a nozzle, then coated to increase adhesion and durability, and then the treated glass fiber filaments are woven into a mesh. During the weaving process, the size of the mesh can be adjusted to suit different application requirements.

Grid cloth manufacturing: Similar to grid cloth, the manufacturing of gingham cloth also starts with the drawing of glass fiber filaments, but the subsequent process is mainly to weave the silk threads into a regular grid through traditional textile equipment. Compared with grid cloth, gingham cloth pays more attention to the uniformity of the grid and the overall flatness during the weaving process.

The open grid structure of fiberglass mesh allows moisture to evaporate, helping to keep the wall dry and reduce the possibility of mold growth. At the same time, this structure also makes the mesh easy to combine with other building materials (such as gypsum board and cement mortar), enhancing the stability of the overall structure. The mesh also has good UV resistance and chemical stability, and can maintain performance for a long time in harsh environments.

Woven fabric has high mechanical properties, including tensile strength, shear strength and bending strength, due to its tight and uniform grid arrangement. This property makes woven fabric an ideal choice for composite material reinforcement. In addition, woven fabric also has good insulation and heat resistance, and is suitable for a variety of industrial application environments.

Functions of fiberglass mesh cloth

1. Crack resistance One of the significant advantages of fiberglass mesh is its crack resistance. In building construction, when concrete or gypsum board is cured, mesh cloth can effectively prevent cracks caused by temperature changes or material shrinkage, improving the durability and aesthetics of the building.

2. Air permeability Due to its mesh structure, fiberglass mesh cloth has good air permeability. This facilitates the drainage of moisture from inside the wall, reducing the risk of mold growth and wall damage caused by excessive humidity.

3. Easy to construct The lightness and softness of the grid cloth make it very easy to cut and fit during the construction process. At the same time, it is compatible with a variety of architectural coatings and mortar materials, allowing construction workers to complete the work quickly.

4. Weather resistance The fiberglass material itself has good weather resistance and is not easily eroded by natural factors such as ultraviolet rays and acid rain. Therefore, the mesh cloth can be used in outdoor environments for a long time without losing its function.

Functions of fiberglass square cloth

1. Enhanced performance Gingham cloth has excellent enhanced performance due to its compact and uniform structure. When combined with resin or other matrix materials, it can significantly improve the tensile strength, compressive strength and impact resistance of composite materials.

2. Heat resistance Fiberglass square cloth has good heat resistance and can maintain its structural integrity in high temperature environments. This property makes it an ideal material for manufacturing high-temperature equipment or components.

3. Insulation As an inorganic non-metallic material, glass fiber has excellent insulation properties. Gingham cloth can be used for electrical insulation, thermal insulation and other applications, especially where protection against current leakage is required.

4. Plasticity Although the structure of composite material is relatively tight, it still has a certain degree of plasticity and can be cut, folded and processed as needed. It is suitable for manufacturing parts with complex shapes.

Functions of fiberglass mesh cloth

1. Crack resistance One of the significant advantages of fiberglass mesh is its crack resistance. In building construction, when concrete or gypsum board is cured, mesh cloth can effectively prevent cracks caused by temperature changes or material shrinkage, improving the durability and aesthetics of the building.

2. Air permeability Due to its mesh structure, fiberglass mesh cloth has good air permeability. This facilitates the drainage of moisture from inside the wall, reducing the risk of mold growth and wall damage caused by excessive humidity.

3. Easy to construct The lightness and softness of the grid cloth make it very easy to cut and fit during the construction process. At the same time, it is compatible with a variety of architectural coatings and mortar materials, allowing construction workers to complete the work quickly.

4. Weather resistance The fiberglass material itself has good weather resistance and is not easily eroded by natural factors such as ultraviolet rays and acid rain. Therefore, the mesh cloth can be used in outdoor environments for a long time without losing its function.

Functions of fiberglass square cloth

1. Enhanced performance Gingham cloth has excellent enhanced performance due to its compact and uniform structure. When combined with resin or other matrix materials, it can significantly improve the tensile strength, compressive strength and impact resistance of composite materials.

2. Heat resistance Fiberglass square cloth has good heat resistance and can maintain its structural integrity in high temperature environments. This property makes it an ideal material for manufacturing high-temperature equipment or components.

3. Insulation As an inorganic non-metallic material, glass fiber has excellent insulation properties. Gingham cloth can be used for electrical insulation, thermal insulation and other applications, especially where protection against current leakage is required.

4. Plasticity Although the structure of checkered cloth is relatively tight, it still has a certain degree of plasticity and can be cut, folded and processed as needed. It is suitable for manufacturing parts with complex shapes.

Fiberglass mesh cloth

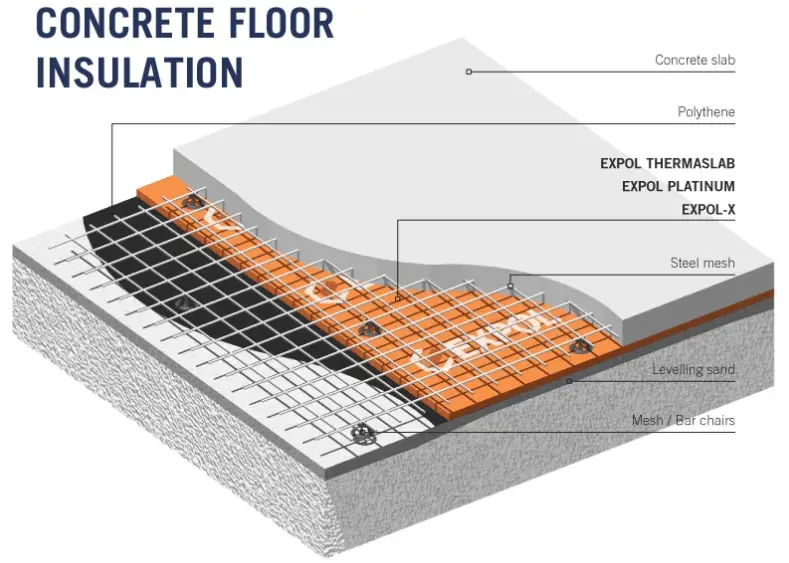

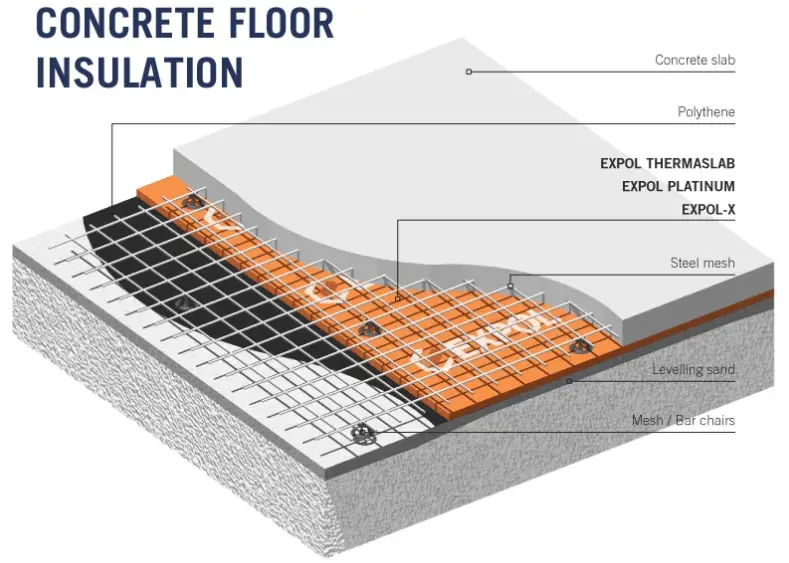

1. Building insulation In the internal and external wall insulation system, fiberglass mesh cloth is widely used to prevent cracks in the wall and improve the insulation effect. It is usually laid on the surface of the exterior wall or interior wall as part of the insulation layer, and works together with the insulation material.

2. Waterproof engineering mesh cloth can also be used in waterproofing projects, such as roof waterproofing, basement waterproofing, etc. It can enhance the stability of the waterproof layer and extend the service life of the waterproof system.

3. Ground laying Before laying the floor or floor tiles, you can lay a layer of fiberglass mesh cloth, which can not only increase the strength of the ground, but also effectively avoid cracking of floor tiles caused by ground settlement or vibration.

4. Decoration In interior decoration, fiberglass mesh cloth can be used in suspended ceilings, partitions and other parts, which not only enhances the safety of the structure, but also has a certain aesthetic effect.

Fiberglass mesh cloth

1. Building insulation In the internal and external wall insulation system, fiberglass mesh cloth is widely used to prevent cracks in the wall and improve the insulation effect. It is usually laid on the surface of the exterior wall or interior wall as part of the insulation layer, and works together with the insulation material.

2. Waterproof engineering mesh cloth can also be used in waterproofing projects, such as roof waterproofing, basement waterproofing, etc. It can enhance the stability of the waterproof layer and extend the service life of the waterproof system.

3. Ground laying Before laying the floor or floor tiles, you can lay a layer of fiberglass mesh cloth, which can not only increase the strength of the ground, but also effectively avoid cracking of floor tiles caused by ground settlement or vibration.

4. Decoration In interior decoration, fiberglass mesh cloth can be used in suspended ceilings, partitions and other parts, which not only enhances the safety of the structure, but also has a certain aesthetic effect.

fiberglass woven roving

1. Composite material reinforcement In the aviation, automobile, shipbuilding and other industries, fiberglass checkered cloth is widely used as a reinforcing material to manufacture aircraft shells, body panels, hull structures and other components. It can significantly improve the strength and toughness of the finished product and reduce its weight.

2. Sports equipment gingham cloth is also used to make golf clubs, snowboards, and bicycles.

Sports equipment such as racks need to be high-strength and lightweight to improve athletes’ performance.

3. Swimming pool introduction

4. Electronic equipment grid cloth can also be used in the manufacture of electronic equipment, such as the base material of printed circuit boards (PCB), using its good electrical insulation properties to ensure the normal operation of the circuit board.

Mesh: Mesh is thin and flexible, making it more flexible during installation and easy to cut and fit onto any surface. This makes mesh more convenient to install, reducing construction time and labor costs.

Grid: Although grid is not as flexible as mesh, its sturdy structure ensures that it will not deform or break easily during installation. For applications that require precise alignment, the advantages of grid are more obvious.

Mesh: Since mesh is breathable, it can reduce problems caused by moisture accumulation, so it is relatively simple to maintain. Just check regularly for damage and repair it in time.

Woven fabric: For woven fabric used as a reinforcement material, the focus of maintenance is to monitor whether it has separated or peeled from the base material. Once a problem is found, measures should be taken to repair it in time to avoid affecting the overall performance.

Operational safety: During the installation process, operators need to pay attention to personal protection and avoid direct contact with glass fiber, as long-term exposure may cause skin irritation or respiratory discomfort.

Safe use: No matter which material is selected, it is necessary to ensure that it meets the relevant standards and specifications to ensure safety during use. Especially for applications that need to withstand large loads, the strength and reliability of the material must be strictly inspected.

Both fiberglass mesh and woven fabric use fiberglass as the main raw material, but there are differences in their production processes. Woven fabric is mainly used in the construction field for internal and external wall insulation systems, waterproofing projects, floor laying, etc., to prevent cracks and enhance structural stability. Woven fabric is widely used in the reinforcement of composite materials, such as aviation, automobiles, shipbuilding, and sports equipment, providing the advantages of high strength and light weight.

As a supplier focusing on providing high-quality fiberglass products, Niumaterial is well aware of the challenges faced by customers when choosing fiberglass mesh and woven fabric. With its high-quality products and services, Niumaterial can help customers better choose materials that suit their needs, thereby achieving the successful implementation of the project. We firmly believe that through continuous efforts and innovations, we can provide more value to customers and promote the healthy development of the industry.

If you have any questions

Please contact us for free consultation and product quotation

Table of Contents Add a h

Table of Contents Add a h