China Supplier wholesales alkali resistant glass fiber chopped strands

Specification

| Item | Diameter(um) | Chopped Length(mm) | Compatible Resin |

| AR Fiberglass chopped strands | 10-13 | 12 | EP UP |

| AR Fiberglass chopped strands | 10-13 | 24 | EP UP |

Product Features

1.Modest water content.Good flowability, even distribution in finished products.

2.Quickly wet-out, high mechanical strength of finished products.Best cost performance.

3.Good bundling: ensure that the product does not fluff and ball in transit.

4. Good dispersibility: good dispersion makes the fibers evenly dispersed when mixed with cement mortar.

5. Excellent physical and chemical properties: it can significantly improve the strength of cement products.

Product Usage

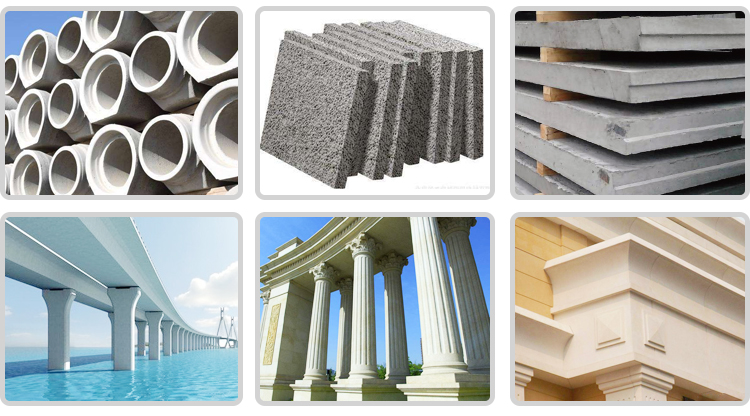

1. The effect of crack initiation and expansion of glass fiber reinforced fluorine concrete. Improve the anti-seepage performance of concrete. Improve the frost performance of concrete. Improve the resistance and toughness of concrete. Improve the durability of concrete.

2. Glass fiber joins cement line, gypsum board, glass steel, composite materials, electrical appliances and other products construction projects, which can be reinforced, anti-crack, wear-resisting and strong.

3. The glass fiber joins the reservoir, the roof slab, the swimming pool, the corruption pool, the sewage treatment pool can improve their service life.

Package&Shipment

1. E-Glass Chopped Strands for pp/pa/pbt are packaged in kraft bags or woven bags, good moisture resistance about 25kg per bag, 4 bags per layer, 8 layers per pallet and 32 bags per pallet, each pallet is packed by multilayer shrink film and packing band.

2. One ton and one bag.

3.Can be customized with logo or 1kg small bag.